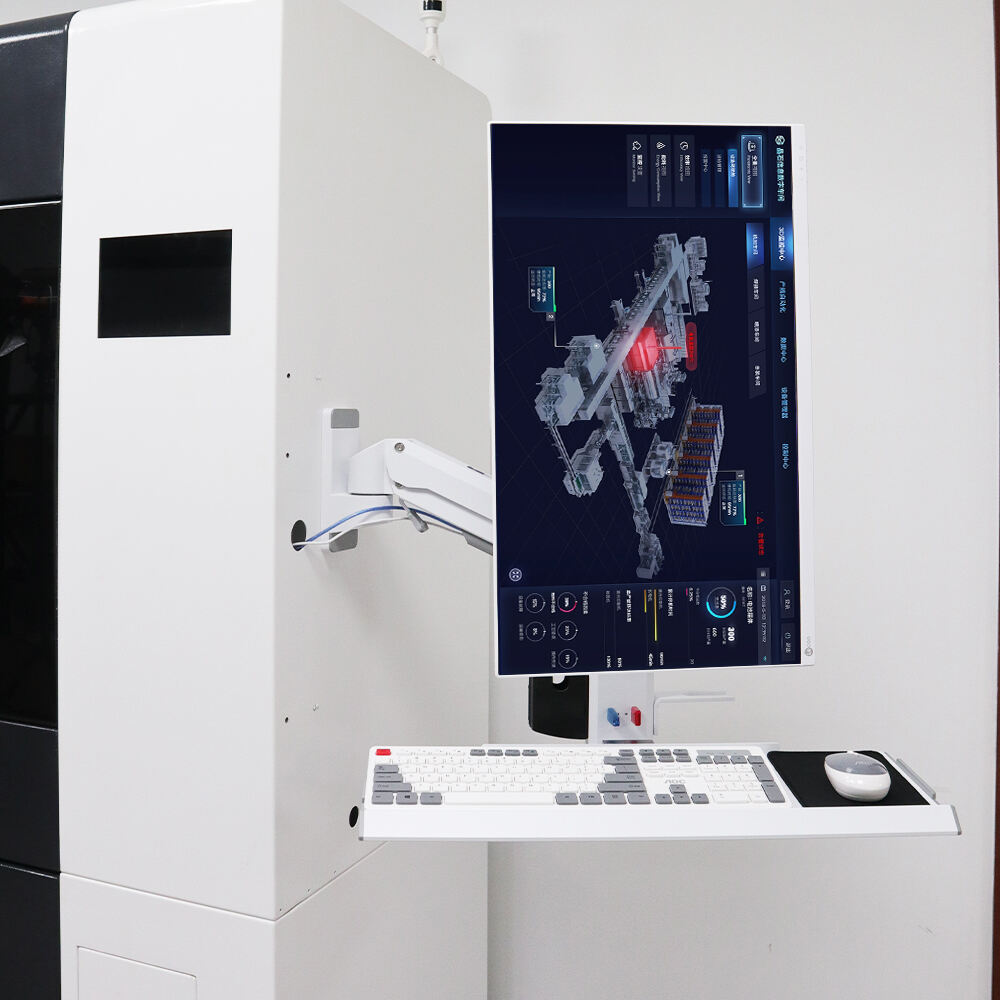

Meisonic Industrial Monitor Bracket Helps Improve Working Efficiency

In modern factories and automation systems, the way your industrial monitor is mounted directly affects efficiency, visibility, and safety. A solid mounting solution helps operators monitor production lines clearly and respond faster.

This guide explains how to mount your industrial monitor and shows why the Meisonic industrial monitor bracket is the ideal choice for professional automation setups.

Why Proper Monitor Mounting Matters

Industrial monitors are vital for displaying real-time data and machine status. Poorly mounted monitors can cause problems such as:

Difficult viewing angles and glare

Unsafe or unstable installations

Cable clutter and damage

Reduced operator comfort and focus

Using a strong and adjustable industrial display mount keeps your system organized and improves overall productivity.

Step-by-Step Guide: How to Mount an Industrial Monitor

1. Choose the Right Mounting Location

Pick a location with clear visibility and easy access. Avoid direct sunlight or high-vibration zones when possible. Proper positioning reduces neck strain and allows operators to work efficiently.

2. Check VESA Mount Compatibility

Most monitors, including Meisonic industrial monitors, follow the VESA mounting standard (such as 75×75 mm or 100×100 mm). Always confirm that your monitor and bracket share the same pattern and load capacity.

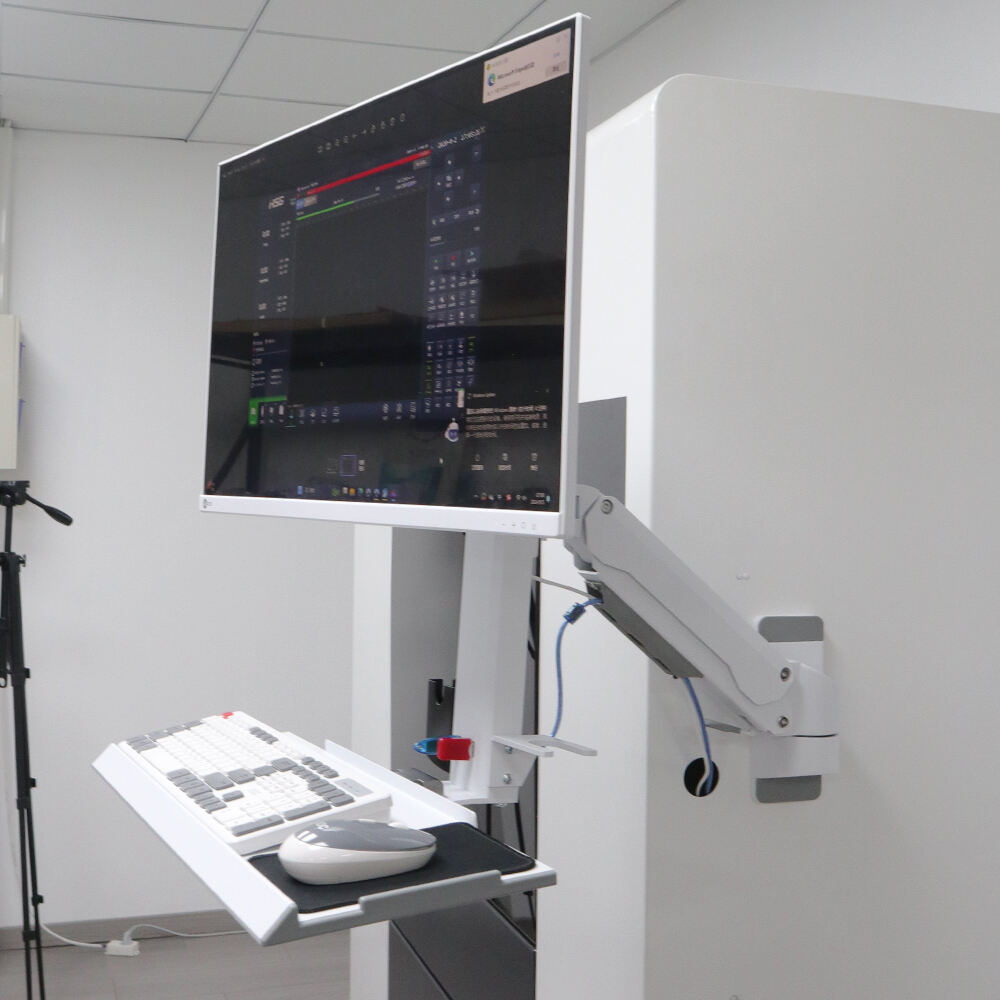

3. Select the Right Bracket Type

Different environments need different mounting solutions:

Fixed Brackets: For permanent, stable installations.

Adjustable Arms: Ideal for operator stations where flexibility is needed.

Panel Mount Kits: For integration into control cabinets or machinery panels.

Meisonic offers all of these, made from industrial-grade materials that ensure long-term durability.

4. Install the Bracket Securely

Use heavy-duty screws or bolts to mount the bracket onto a solid surface. Make sure it’s level and tight to prevent monitor movement. In high-vibration environments, use anti-vibration pads for added stability.

5. Mount the Monitor and Manage Cables

Attach your monitor using the correct screws and double-check alignment. Organize cables with clips or sleeves to keep them safe, tidy, and easy to maintain.

Advantages of Meisonic Industrial Monitor Brackets

1.Durable Design – Built with strong steel or aluminum for maximum support.

2.Ergonomic Adjustment – Allows tilt, swivel, and rotation for comfortable viewing angles.

3.Easy Maintenance – Quick installation and removal reduce downtime.

4.Cable Management System – Keeps wires neat and prevents wear.

5.Wide Compatibility – Fits most VESA-compatible industrial displays.

By using Meisonic brackets, your factory or automation line becomes more organized and efficient.

Where to Use Meisonic Monitor Brackets

Meisonic brackets are widely used in:

Factory automation and assembly lines

Packaging and labeling machines

Food and beverage production systems

Machine vision and inspection equipment

Warehouse monitoring and logistics centers

In every setup, a well-mounted monitor ensures faster decision-making, fewer errors, and a safer working environment.

Conclusion

Mounting your industrial monitor correctly is an easy way to improve productivity and safety in automation. The Meisonic industrial monitor bracket offers strength, flexibility, and long-lasting performance, making it an excellent solution for professional automation systems.

Upgrade your setup today with Meisonic industrial monitor brackets — a simple way to make your workspace more efficient, organized, and operator-friendly.