Transforming Warehouse Operations with Advanced Mounting Solutions

Modern warehousing and logistics centers are increasingly embracing technological solutions to streamline their operations and boost efficiency. At the heart of this transformation lies the industrial monitor mount, a crucial component that enables seamless integration of digital displays and information systems throughout the facility. These robust mounting solutions provide the foundation for creating smart, connected warehouses that can meet the demanding requirements of today's fast-paced supply chain industry.

The strategic implementation of industrial monitor mount systems has revolutionized how warehouse staff interact with crucial data and control systems. From inventory management to order fulfillment, these mounting solutions ensure that vital information is readily accessible while maintaining a safe and organized workspace. The impact of proper monitor mounting extends far beyond mere convenience – it directly influences productivity, worker safety, and operational efficiency.

Core Benefits of Industrial Monitor Mounts in Warehouse Settings

Enhanced Workspace Optimization

The implementation of industrial monitor mount solutions plays a pivotal role in maximizing available space within warehousing facilities. By elevating monitors off desks and workstations, these mounts create additional usable surface area for other essential tasks. This space-saving advantage is particularly valuable in compact sorting stations and shipping areas where every square foot matters.

Furthermore, industrial monitor mount installations allow for strategic placement of displays at optimal viewing heights and angles. This flexibility enables warehouse managers to design ergonomic workstations that accommodate different user preferences and operational requirements. The ability to adjust monitor positions helps reduce neck strain and promotes better posture among warehouse staff during extended work hours.

Improved Operational Efficiency

When properly installed, industrial monitor mount systems contribute significantly to workflow optimization. By positioning screens at strategic locations throughout the facility, workers can access real-time information without unnecessary movement or delay. This immediate access to inventory data, shipping details, and operational metrics helps reduce response times and minimize errors in order processing.

The durability of industrial monitor mount solutions ensures consistent performance even in challenging warehouse environments. These mounts are designed to withstand vibrations from nearby machinery, protect against accidental impacts, and maintain stable viewing angles despite frequent activity in the surrounding area. This reliability translates directly into reduced downtime and maintenance requirements.

Integration with Modern Warehouse Management Systems

Digital Interface Enhancement

Modern warehouse management systems rely heavily on digital interfaces to coordinate various aspects of operations. Industrial monitor mount installations facilitate seamless integration of these interfaces by providing stable, adjustable platforms for displays throughout the facility. This integration enables real-time tracking of inventory movements, order status updates, and worker productivity metrics.

The flexibility of industrial monitor mount solutions allows warehouses to adapt their digital infrastructure as technology evolves. Whether implementing new software systems or upgrading to larger displays, these mounts can accommodate changing requirements without major modifications to the existing setup. This adaptability ensures that warehouses can maintain competitive advantages through technological advancement.

Data Visualization and Control Centers

Warehouse control centers benefit significantly from industrial monitor mount implementations. These mounting solutions enable the creation of comprehensive monitoring stations where multiple screens can be arranged for optimal visibility. Supervisors can simultaneously track various operational aspects, from security camera feeds to inventory levels and shipping schedules.

The professional-grade construction of industrial monitor mount systems ensures stable support for multiple displays, even in continuous operation scenarios. This reliability is crucial for maintaining uninterrupted surveillance and monitoring of warehouse activities. The ability to adjust viewing angles and screen positions helps create ergonomic control center layouts that enhance operator efficiency and comfort.

Safety and Compliance Considerations

Structural Integrity and Installation Standards

The implementation of industrial monitor mount solutions must adhere to strict safety standards and building codes. Professional installation ensures that mounting points can support the weight of displays and withstand the dynamic environment of warehouse operations. Regular inspections and maintenance procedures help verify the continued stability and security of mounted equipment.

Quality industrial monitor mount systems incorporate safety features such as locking mechanisms and cable management solutions. These features prevent accidental displacement of screens and reduce potential hazards from loose cables in high-traffic areas. The robust construction of these mounts provides peace of mind for facility managers responsible for maintaining safe working conditions.

Ergonomic Considerations and Worker Safety

The proper positioning of monitors through industrial mount solutions plays a crucial role in preventing workplace injuries and promoting employee well-being. Adjustable mounting systems allow workers to customize screen positions according to their individual needs, reducing the risk of repetitive strain injuries and visual fatigue.

Industrial monitor mount installations contribute to cleaner, more organized workspaces by eliminating cluttered desk surfaces and tangled cables. This organization not only improves safety but also creates a more professional and efficient working environment. The reduced risk of accidents and improved ergonomics can lead to decreased worker compensation claims and increased job satisfaction.

Future Trends and Innovations

Advanced Mounting Technologies

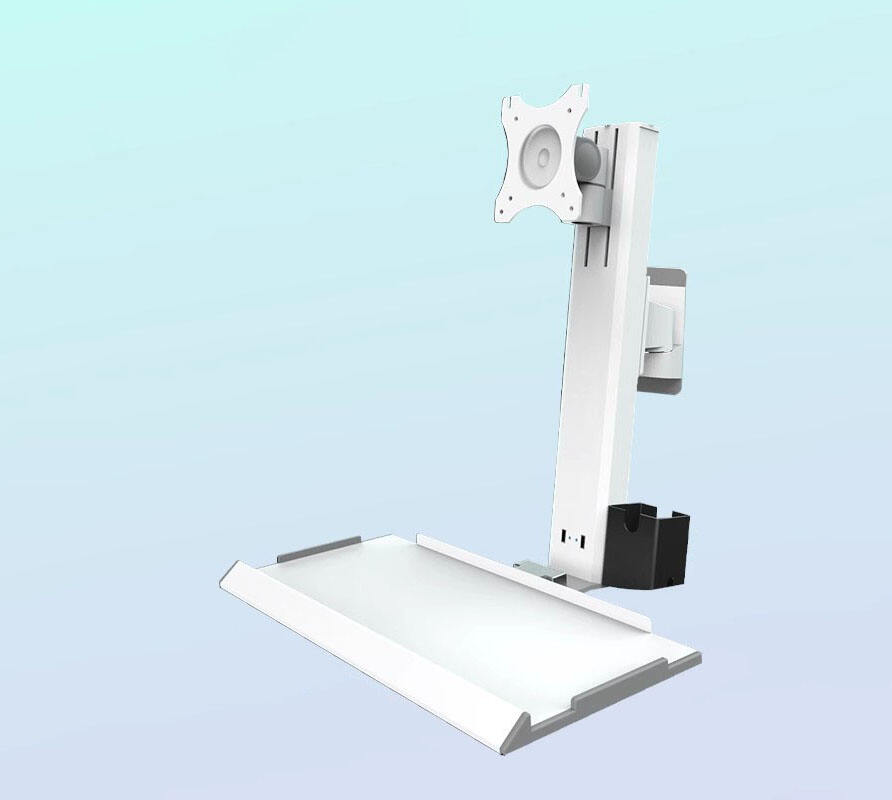

The evolution of industrial monitor mount solutions continues to keep pace with technological advancements in warehouse operations. Newer models incorporate features such as integrated power delivery, enhanced cable management, and compatibility with touchscreen interfaces. These innovations support the growing trend toward more interactive and connected warehouse management systems.

Future developments in industrial monitor mount technology may include smart adjustment capabilities, allowing automatic optimization of viewing angles based on user preferences or ambient conditions. The integration of IoT sensors could enable predictive maintenance and real-time monitoring of mount stability, further enhancing reliability and safety.

Sustainability and Adaptability

Modern industrial monitor mount solutions increasingly incorporate sustainable materials and energy-efficient designs. Manufacturers are focusing on creating products that not only meet current operational needs but also align with environmental responsibility goals. This trend reflects the growing emphasis on sustainable warehouse operations across the logistics industry.

The adaptability of current industrial monitor mount systems positions warehouses for future technological integration. Whether accommodating larger displays, supporting augmented reality systems, or incorporating new control interfaces, these mounting solutions provide the foundation for continued innovation in warehouse operations.

Frequently Asked Questions

What factors should be considered when selecting industrial monitor mounts for warehouse use?

When choosing industrial monitor mounts for warehouse applications, consider factors such as weight capacity, adjustability range, durability in industrial environments, ease of installation, and compatibility with existing infrastructure. Additionally, evaluate the specific requirements of your operation, including viewing distance, ambient lighting conditions, and potential exposure to dust or vibration.

How do industrial monitor mounts contribute to warehouse productivity?

Industrial monitor mounts enhance warehouse productivity by optimizing workspace organization, improving information accessibility, reducing worker fatigue through ergonomic positioning, and enabling efficient multi-screen setups for control centers. These benefits lead to faster order processing, reduced errors, and improved overall operational efficiency.

What maintenance requirements exist for industrial monitor mounting systems?

Regular maintenance for industrial monitor mounts includes checking mounting hardware tightness, inspecting cable management systems, verifying adjustment mechanism functionality, and ensuring overall structural integrity. It's recommended to conduct visual inspections monthly and perform detailed maintenance checks quarterly or as specified by the manufacturer.