Modern commercial and professional environments demand robust, reliable solutions for mounting displays and monitors. An industrial monitor mount represents a critical component in creating efficient workspaces across manufacturing facilities, control rooms, healthcare settings, and various industrial applications. These specialized mounting systems provide superior stability, adjustability, and durability compared to standard consumer-grade alternatives, making them indispensable for mission-critical operations where reliability cannot be compromised.

The evolution of workplace technology has significantly increased the importance of proper monitor positioning and support systems. From production line monitoring to data analysis stations, the need for versatile and durable mounting solutions continues to grow. Industrial environments present unique challenges including vibration, temperature fluctuations, dust, and continuous operation requirements that standard mounting systems simply cannot address effectively.

Understanding Industrial Monitor Mount Applications

Manufacturing and Production Environments

Manufacturing facilities rely heavily on real-time monitoring systems to track production metrics, quality control parameters, and safety protocols. An industrial monitor mount in these settings must withstand constant vibration from machinery, temperature variations, and exposure to industrial particles. These mounts support displays showing production dashboards, quality metrics, and safety alerts that operators need to access quickly and clearly throughout their shifts.

The positioning flexibility offered by quality industrial monitor mounts becomes crucial when operators need to adjust viewing angles for different tasks or shift changes. Gas spring mechanisms allow smooth repositioning without tools, enabling workers to optimize screen placement for various operational requirements. This adaptability directly impacts productivity and reduces operator fatigue during extended work periods.

Control Room and Command Centers

Control rooms in power plants, transportation hubs, and security centers require multiple monitor configurations that can be adjusted for optimal viewing by different operators. An industrial monitor mount system in these environments must support extended operation periods while maintaining precise positioning capabilities. The reliability of these mounting systems directly impacts the effectiveness of critical monitoring operations.

Advanced industrial monitor mount designs incorporate cable management features that keep workstations organized and professional. This organization proves essential in high-stakes environments where quick access to controls and clear sight lines can impact decision-making speed and accuracy. The ability to quickly reconfigure monitor positions also supports shift changes and emergency response protocols.

Key Features and Design Considerations

Durability and Construction Standards

The construction quality of an industrial monitor mount must exceed standard office equipment specifications to handle demanding operational conditions. High-grade steel construction with corrosion-resistant finishes ensures longevity in harsh environments where standard mounts would quickly deteriorate. These mounts undergo rigorous testing for load capacity, vibration resistance, and temperature cycling to meet industrial reliability standards.

Weight capacity represents a critical specification, as industrial displays often feature reinforced housings and larger screen sizes compared to consumer monitors. Professional industrial monitor mount systems typically support significantly higher weight loads while maintaining smooth adjustment mechanisms throughout their operational life. This robust construction prevents mount failure that could result in expensive equipment damage and operational downtime.

Ergonomic Adjustability and User Interface

Ergonomic design principles guide the development of professional industrial monitor mount systems to reduce operator strain and improve productivity. Height adjustment, tilt control, and rotation capabilities allow users to position displays at optimal viewing angles for their specific tasks and physical requirements. These adjustments must remain smooth and precise even after thousands of repositioning cycles.

Gas spring technology provides effortless monitor positioning while maintaining secure hold at any adjusted position. This technology eliminates the need for manual tightening of adjustment mechanisms, allowing operators to quickly reposition displays during shift changes or task transitions. The smooth operation of these systems contributes to a more professional and efficient work environment.

Installation and Integration Benefits

Space Optimization and Workflow Enhancement

Implementing a properly designed industrial monitor mount system creates significant space savings compared to traditional desk-mounted displays. Wall and desk-mounted configurations free up valuable work surface area while providing superior adjustability and viewing options. This space efficiency becomes particularly valuable in compact control rooms and workstations where every square foot impacts operational effectiveness.

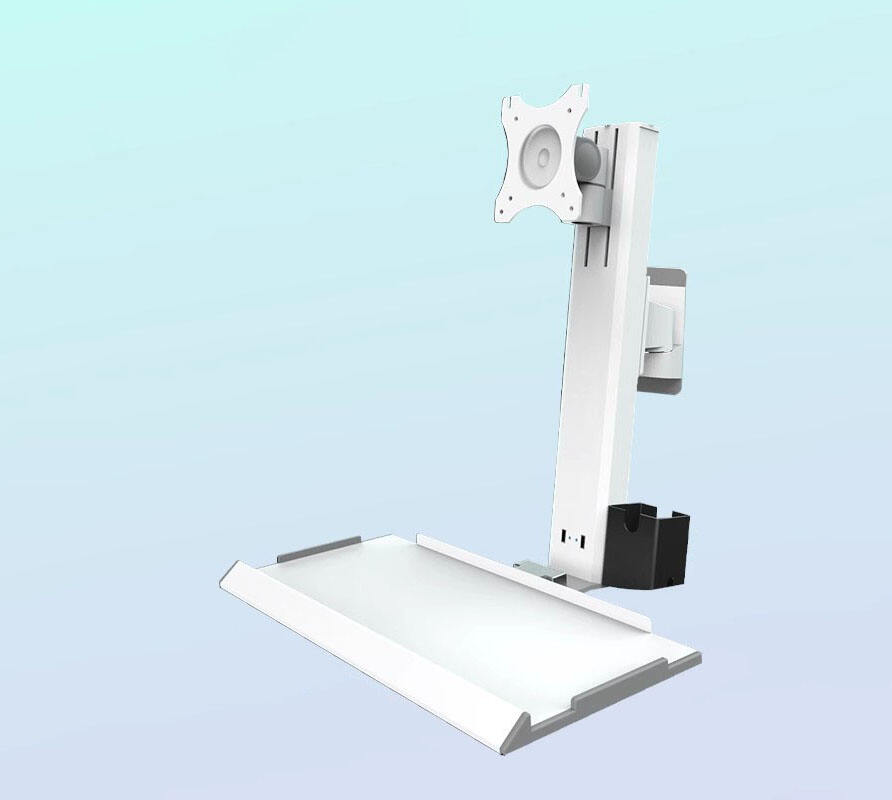

The integration capabilities of modern industrial monitor mount systems support multiple accessories including keyboard trays, document holders, and additional display arms. This modular approach allows facilities to create customized workstation configurations that match specific operational requirements without requiring custom fabrication or extensive modifications to existing infrastructure.

Maintenance and Operational Efficiency

Professional industrial monitor mount systems simplify maintenance procedures through accessible adjustment mechanisms and durable component design. The ability to easily reposition or temporarily relocate displays facilitates equipment servicing, cleaning, and workspace reconfiguration without requiring specialized tools or extensive downtime. This maintenance efficiency directly impacts operational continuity and cost management.

Long-term operational costs benefit significantly from quality industrial monitor mount installations through reduced replacement frequency and lower maintenance requirements. The initial investment in professional-grade mounting systems typically provides substantial returns through improved reliability, extended equipment life, and reduced operational disruptions compared to cheaper alternatives that require frequent replacement or repair.

Safety and Compliance Considerations

Workplace Safety Standards

Industrial environments mandate strict adherence to safety standards that impact equipment selection and installation procedures. An industrial monitor mount must meet relevant safety certifications and load capacity requirements to ensure operator protection and regulatory compliance. These standards address factors including seismic resistance, electrical safety, and emergency egress requirements that vary by industry and geographic location.

Proper installation procedures for industrial monitor mount systems require consideration of structural load limits, electrical routing, and emergency access requirements. Professional installation ensures compliance with applicable codes while optimizing system performance and safety. The documentation and certification provided with quality mounting systems support regulatory inspections and insurance requirements.

Risk Mitigation and Equipment Protection

The failure of mounting systems in industrial environments can result in significant equipment damage, operational disruptions, and potential safety hazards. Quality industrial monitor mount designs incorporate multiple safety features including redundant support mechanisms, controlled failure modes, and clearly defined load limits that prevent catastrophic failures. These safety features represent essential risk mitigation measures in critical operational environments.

Environmental protection capabilities of professional industrial monitor mount systems extend equipment life and maintain operational reliability in challenging conditions. Features such as sealed adjustment mechanisms, corrosion-resistant finishes, and vibration dampening contribute to consistent performance and reduced maintenance requirements throughout the system's operational life.

Selection Criteria and Specification Guidelines

Technical Requirements Assessment

Selecting an appropriate industrial monitor mount requires careful evaluation of specific operational requirements including display size and weight, adjustment frequency, environmental conditions, and integration needs. Load capacity specifications must include safety margins that account for dynamic loading conditions and potential equipment upgrades. The mounting interface compatibility ensures proper fit with existing displays and future equipment changes.

Environmental factors significantly influence industrial monitor mount selection criteria including temperature ranges, vibration levels, exposure to chemicals or moisture, and electromagnetic interference considerations. These factors determine the required construction materials, protective coatings, and sealed component specifications necessary for reliable long-term operation in specific industrial environments.

Cost-Benefit Analysis and ROI Considerations

The total cost of ownership for an industrial monitor mount system includes initial purchase price, installation costs, maintenance requirements, and replacement frequency over the system's operational life. Quality mounting systems typically provide superior return on investment through extended service life, reduced maintenance needs, and improved operational efficiency compared to lower-cost alternatives that require frequent replacement.

Productivity benefits from properly implemented industrial monitor mount systems include reduced operator fatigue, improved workspace efficiency, and enhanced equipment accessibility for maintenance procedures. These operational improvements often justify the higher initial investment in professional-grade mounting systems through measurable improvements in productivity and reduced operational costs.

Future Trends and Technology Integration

Smart Manufacturing and Industry 4.0 Integration

The evolution toward smart manufacturing and Industry 4.0 initiatives increases the importance of flexible display mounting solutions that can adapt to changing technological requirements. Modern industrial monitor mount systems must accommodate various display technologies, connection interfaces, and positioning requirements as manufacturing facilities integrate advanced monitoring and control systems.

Integration capabilities with IoT sensors, automated positioning systems, and remote monitoring technologies represent emerging features in advanced industrial monitor mount designs. These capabilities support predictive maintenance programs, automated workspace configuration, and remote operational monitoring that align with modern industrial digitization initiatives.

Sustainability and Environmental Responsibility

Environmental considerations increasingly influence industrial equipment selection including monitor mounting systems. Sustainable manufacturing practices, recyclable materials, and energy-efficient production methods represent important factors in evaluating industrial monitor mount options. Long product lifecycles and upgrade compatibility contribute to reduced environmental impact through decreased replacement frequency and waste generation.

The durability and longevity of quality industrial monitor mount systems align with corporate sustainability goals by reducing equipment turnover and associated environmental impacts. Investment in durable mounting solutions supports both operational efficiency and environmental responsibility objectives while maintaining the performance standards required for industrial applications.

FAQ

What weight capacity should I consider for an industrial monitor mount?

Industrial monitor mount weight capacity should exceed your display weight by at least 50% to ensure safety margins for dynamic loading and potential equipment upgrades. Most industrial applications require mounts supporting 20-100 pounds depending on display size and configuration. Consider future display upgrades when selecting weight capacity specifications to avoid premature replacement needs.

How do gas spring mechanisms improve industrial monitor mount performance?

Gas spring technology provides smooth, effortless monitor positioning while maintaining secure hold at any adjusted position. This eliminates manual tightening requirements and allows quick repositioning during shift changes or task transitions. Gas springs maintain consistent performance through thousands of adjustment cycles, making them ideal for frequently adjusted industrial applications.

What environmental factors affect industrial monitor mount selection?

Key environmental considerations include temperature ranges, vibration levels, exposure to dust or chemicals, humidity conditions, and electromagnetic interference. Industrial environments often require specialized coatings, sealed components, and enhanced construction materials to ensure reliable operation. Proper environmental assessment ensures mount selection matches specific operational conditions and extends system life.

How does proper cable management impact industrial monitor mount installations?

Integrated cable management features maintain organized, professional workstations while protecting cables from damage during monitor adjustments. Proper cable routing prevents interference with adjustment mechanisms and reduces wear from repeated positioning cycles. Clean cable management also supports maintenance procedures and regulatory compliance in industrial environments where organization and accessibility are critical.