Le strutture sanitarie in tutto il mondo dipendono dall'uso di apparecchiature mediche mobili per fornire cure critiche ai pazienti in modo efficiente. Gli ambienti medici moderni richiedono soluzioni sofisticate montaggio del display soluzioni in grado di resistere alle condizioni impegnative degli ospedali, delle cliniche e dei veicoli per le emergenze. L'evoluzione della tecnologia dei supporti per monitor su carrelli medici ha rivoluzionato il modo in cui i professionisti sanitari accedono a informazioni digitali, cartelle cliniche e immagini diagnostiche direttamente al letto del paziente. Questi sistemi di montaggio avanzati devono garantire stabilità, flessibilità e durata, mantenendo al contempo capacità di posizionamento preciso durante periodi prolungati di utilizzo.

L'integrazione della tecnologia digitale negli ambienti sanitari ha creato esigenze senza precedenti per soluzioni di montaggio affidabili. I professionisti del settore medico necessitano di un accesso immediato ai dati dei pazienti, alle immagini diagnostiche e ai fascicoli sanitari elettronici durante gli spostamenti tra le aree di trattamento. Sistemi di montaggio di alta qualità per monitor consentono transizioni fluide nel flusso di lavoro, riducendo i tempi di risposta e migliorando i risultati complessivi per il paziente. Il posizionamento strategico dei display su carrelli medicali e veicoli per anestesia influisce direttamente sull'efficienza operativa e sui processi decisionali clinici.

Tecnologia avanzata a molle a gas per applicazioni mediche

Sistemi pneumatici di stabilità

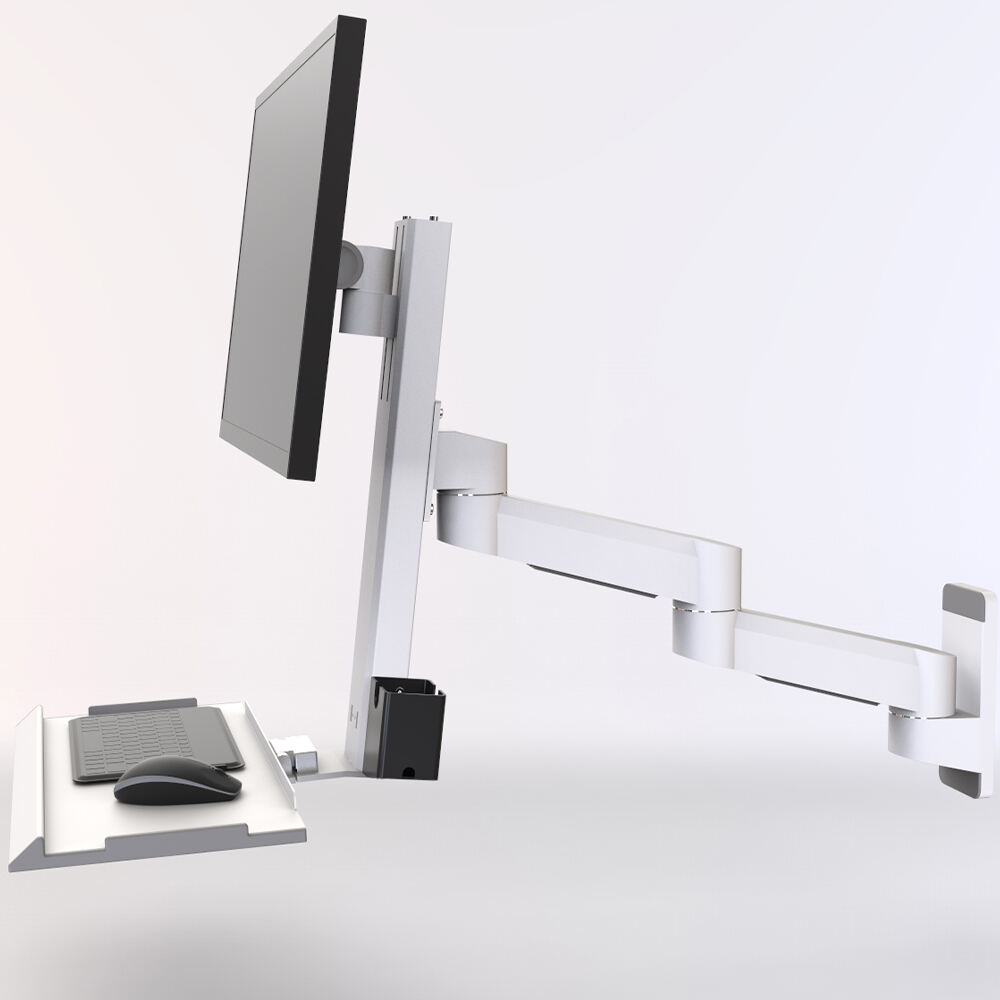

I meccanismi a molla a gas rappresentano il massimo della tecnologia di montaggio per monitor negli ambienti medici. Questi sofisticati sistemi utilizzano camere di azoto compresso per garantire movimenti fluidi e controllati, mantenendo al contempo un'eccezionale stabilità durante l'utilizzo. Il design pneumatico elimina i movimenti bruschi tipici dei tradizionali sistemi meccanici, assicurando che i display medici sensibili rimangano perfettamente posizionati anche durante spostamenti rapidi del carrello o situazioni di emergenza. I professionisti sanitari beneficiano di regolazioni dell'altezza senza sforzo e di capacità di posizionamento preciso, che migliorano il comfort ergonomico durante procedure prolungate.

Le camere a gas sigillate nei sistemi di montaggio premium resistono al contaminante e mantengono prestazioni costanti per migliaia di cicli di regolazione. Le strutture mediche richiedono apparecchiature in grado di sopportare frequenti pulizie con disinfettanti di qualità ospedaliera senza compromettere l'integrità operativa. La tecnologia avanzata delle molle a gas incorpora materiali resistenti alla corrosione e sistemi di tenuta specializzati che proteggono i componenti interni dall'esposizione chimica mantenendo nel contempo un funzionamento fluido per lunghi periodi di servizio.

Ingegneria della Capacità di Carico

I sistemi professionali di montaggio per monitor su carrelli medici devono supportare pesi variabili dei display mantenendo la stabilità in diverse applicazioni. Le specifiche tecniche prevedono generalmente display leggeri tipo tablet fino a monitor diagnostici pesanti che possono superare i 30 libbre. Il meccanismo a molla a gas compensa automaticamente carichi diversi, fornendo un'assistenza sollevamento costante indipendentemente dal peso del display collegato. Questa capacità adattiva garantisce ai professionisti sanitari di riposizionare facilmente i display senza sforzi fisici eccessivi o rischio di danneggiamento dell'apparecchiatura.

La tecnologia di bilanciamento del carico impedisce cali improvvisi o movimenti inaspettati che potrebbero mettere a rischio sia l'attrezzatura che il personale. I sistemi di montaggio premium incorporano molle a gas multistadio che offrono una resistenza progressiva lungo tutta l'escursione di movimento. Questo approccio ingegneristico sofisticato garantisce un funzionamento fluido sia durante la regolazione dell'altezza del display per posizioni in piedi o sedute, soddisfacendo diverse preferenze utente e requisiti clinici senza compromettere gli standard di sicurezza o prestazioni.

Vantaggi della Costruzione in Lega di Alluminio

Caratteristiche di Resistenza del Materiale

Le leghe di alluminio di grado aerospaziale offrono rapporti eccezionali tra resistenza e peso, essenziali per le applicazioni di montaggio medico. Questi materiali avanzati resistono alla corrosione, mantengono l'integrità strutturale sotto cicli ripetuti di sollecitazione e offrono una durata superiore rispetto alle tradizionali alternative in acciaio. La natura leggera della costruzione in alluminio riduce il peso complessivo del carrello mantenendo al contempo la robustezza supporto necessario per il montaggio sicuro del display. Le strutture mediche beneficiano di una maggiore manovrabilità del carrello senza sacrificare la stabilità richiesta per le applicazioni di cure critiche.

La struttura cristallina delle leghe di alluminio opportunamente trattate garantisce prestazioni costanti alle variazioni di temperatura comunemente riscontrate negli ambienti sanitari. Dalle sale operatorie con climatizzazione controllata ai contesti di emergenza all'aperto, i sistemi di montaggio di qualità mantengono le loro proprietà meccaniche indipendentemente dalle condizioni ambientali. I trattamenti superficiali e i processi di anodizzazione migliorano ulteriormente la resistenza alla corrosione, assicurando un'affidabilità a lungo termine in ambienti medici impegnativi dove pulizia e disinfezione frequenti sono requisiti obbligatori.

Standard di Precisione Produttiva

I processi di lavorazione CNC garantiscono precisione dimensionale e qualità costante in tutti i componenti del sistema di montaggio. La produzione di precisione elimina giochi e oscillazioni che potrebbero compromettere la stabilità del display durante il funzionamento. Tolleranze strette nelle giunzioni e nei punti di rotazione assicurano un funzionamento fluido prevenendo l'usura prematura, che potrebbe portare al malfunzionamento del sistema. Gli ambienti medici richiedono standard di affidabilità superiori rispetto alle tipiche applicazioni commerciali, necessitando processi produttivi in grado di garantire prestazioni costanti su migliaia di unità.

I protocolli di controllo qualità nella produzione di sistemi di montaggio medici includono procedure di test complete che ne convalidano la capacità di carico, l'escursione di movimento e le specifiche di durata. Ogni componente è sottoposto a ispezioni rigorose per garantire la conformità agli standard dei dispositivi medici e ai requisiti di sicurezza. L'approccio produttivo di precisione consente di ottenere sistemi di montaggio che mantengono nel tempo le proprie capacità di regolazione e integrità strutturale durante lunghi periodi di utilizzo in applicazioni sanitarie gravose.

Considerazioni sul Design Ergonomico

Ottimizzazione dell'interfaccia utente

I professionisti del settore sanitario necessitano di meccanismi di regolazione intuitivi che consentano un posizionamento rapido dei display senza interrompere i flussi di lavoro assistenziali. I moderni sistemi di montaggio per monitor su carrelli medicali integrano design ergonomici delle maniglie e meccanismi di regolazione fluidi che riducono lo sforzo fisico massimizzando la precisione di posizionamento. La possibilità di funzionamento con una sola mano permette al personale medico di mantenere il contatto con il paziente mentre regola angoli e altezze del display per ottimizzare le condizioni di visione durante specifiche procedure o consultazioni.

L'integrazione di meccanismi di feedback tattile aiuta gli utenti a raggiungere un posizionamento preciso anche in condizioni di scarsa illuminazione o quando l'attenzione deve rimanere concentrata sull'assistenza al paziente. I sistemi di montaggio di qualità offrono livelli di resistenza costanti che danno agli operatori sicurezza nelle regolazioni, senza richiedere la conferma visiva delle posizioni dei comandi. Questa operatività intuitiva riduce i requisiti di formazione e consente ai professionisti sanitari di concentrarsi sull'assistenza al paziente piuttosto che sulla manipolazione dell'apparecchiatura.

Integrazione nello Spazio di Lavoro

Le soluzioni efficaci per il montaggio dei monitor si integrano perfettamente con i design esistenti dei carrelli medici senza compromettere la funzionalità o aggiungere complessità non necessarie. Profili di montaggio compatti massimizzano lo spazio di lavoro disponibile pur offrendo una completa gamma di movimenti. Il posizionamento strategico dei punti di rotazione e dei meccanismi di regolazione garantisce che i display possano essere posizionati in modo ottimale senza interferire con altri dispositivi medici o limitare l'accesso a vani di stoccaggio e superfici di lavoro.

I sistemi di gestione dei cavi integrati in soluzioni di montaggio di qualità mantengono i collegamenti ordinati, consentendo al contempo l'intera gamma di movimenti del display. Un corretto instradamento dei cavi evita annodamenti o danni durante le operazioni di regolazione, mantenendo un aspetto pulito e professionale che rispecchia gli elevati standard richiesti negli ambienti medici. Queste considerazioni progettuali contribuiscono all'efficienza complessiva del flusso di lavoro e alla longevità delle attrezzature in applicazioni sanitarie impegnative.

Caratteristiche di Installazione e Compatibilità

Standard universali di montaggio

La compatibilità VESA garantisce una vasta compatibilità con display di diversi marchi e dimensioni comunemente utilizzati negli ambienti sanitari. Gli standard di montaggio eliminano problemi di compatibilità offrendo al contempo flessibilità per futuri aggiornamenti o sostituzioni delle apparecchiature. I sistemi professionali di montaggio supportano più pattern VESA all'interno di un'unica unità, garantendo protezione dell'investimento e flessibilità operativa per strutture mediche con esigenze diverse di visualizzazione.

Le piastrine adattatrici e gli accessori di montaggio ampliano le opzioni di compatibilità per display medici specializzati o apparecchiature obsolete che potrebbero non essere conformi agli attuali standard VESA. I sistemi di montaggio di qualità includono kit hardware completi in grado di adattarsi a diverse situazioni di installazione, senza richiedere acquisti aggiuntivi o modifiche. Questo approccio completo semplifica i processi di approvvigionamento e garantisce risultati di installazione affidabili su svariate configurazioni di carrelli medicali.

Metodi di integrazione sui carrelli

Meccanismi di serraggio robusti assicurano un fissaggio sicuro ai binari e alle superfici dei carrelli medicali senza modifiche permanenti. Morsetti di qualità professionale si adattano a diverse dimensioni e configurazioni di binari dei carrelli, offrendo al contempo la possibilità di installazione e rimozione senza l'uso di utensili. Questa flessibilità consente alle strutture mediche di riconfigurare assegnazioni delle apparecchiature o spostare i sistemi di montaggio tra diversi carrelli in base alle esigenze operative.

Le piastre di rinforzo e i meccanismi di distribuzione evitano la concentrazione di sollecitazioni che potrebbero danneggiare le strutture del carrello o compromettere la sicurezza del montaggio. I sistemi di qualità includono imbottiture protettive e trattamenti superficiali che prevengono graffi o segni sulle finiture del carrello, mantenendo al contempo un fissaggio sicuro in condizioni di carico dinamico. Queste caratteristiche di installazione garantiscono una compatibilità a lungo termine con gli investimenti in carrelli medicali, offrendo al contempo capacità affidabili di montaggio per i display.

Fattori di Manutenzione e Longevità

Protocolli di Prevenzione

Pianificazioni regolari di manutenzione assicurano prestazioni ottimali ed estendono la durata dei sistemi di montaggio medici. Semplici procedure di pulizia con disinfettanti ospedalieri approvati mantengono gli standard igienici senza compromettere la funzionalità meccanica. Ispezioni periodiche dei meccanismi di regolazione e dei punti di montaggio identificano eventuali problemi prima che possano influire sulle operazioni cliniche o compromettere la sicurezza del paziente.

I requisiti di lubrificazione per sistemi di montaggio di qualità sono minimi grazie a progetti avanzati dei cuscinetti e meccanismi sigillati che resistono al contaminante. Quando è necessaria manutenzione, lubrificanti di grado alimentare compatibili con ambienti medici garantiscono un funzionamento continuo e regolare senza introdurre sostanze nocive negli ambienti sanitari. La documentazione delle attività di manutenzione supporta la conformità alle normative sui dispositivi medici e ai programmi di assicurazione della qualità.

Aspettative sulla Durata dell'Utilizzo

I sistemi premium di montaggio per monitor su carrelli medicali offrono un servizio affidabile per molti anni in condizioni normali di utilizzo sanitario. La copertura della garanzia riflette tipicamente la fiducia del produttore nella durata e nella costanza prestazionale del prodotto. I calcoli relativi alla vita utile prevista tengono conto della natura impegnativa degli ambienti medici e dell'importanza fondamentale di un funzionamento affidabile delle apparecchiature negli ambienti sanitari.

La disponibilità di parti di ricambio garantisce il proseguimento dell'operatività anche quando i componenti subiscono usura normale nel corso di lunghi periodi di servizio. I produttori di qualità mantengono inventari completi di pezzi di ricambio e offrono supporto tecnico per massimizzare la disponibilità delle attrezzature e ridurre al minimo le interruzioni operative. Questo impegno di supporto a lungo termine fornisce alle strutture mediche fiducia negli investimenti effettuati sulle attrezzature e nelle capacità di pianificazione operativa.

Domande Frequenti

Quale capacità di carico devo aspettarmi da un supporto di qualità per monitor su carrello medico?

I sistemi professionali di montaggio su carrello medico supportano tipicamente display dal peso compreso tra 4,5 e 13,6 kg, con modelli premium che accolgono monitor diagnostici più pesanti fino a 15,9 kg. Il meccanismo a molla a gas si regola automaticamente a seconda del carico, garantendo prestazioni costanti indipendentemente dal peso del display. Verificare sempre le specifiche capacità di carico per il display previsto prima dell'installazione, per assicurare prestazioni ottimali e sicurezza.

Come faccio a garantire la compatibilità con il mio carrello medico esistente?

La maggior parte dei sistemi di montaggio di qualità include meccanismi di serraggio regolabili che si adattano alle dimensioni standard dei binari dei carrelli medicali, con spessori compresi tra 0,5 e 2 pollici. Misurare le dimensioni del binario del carrello e verificare la compatibilità con le specifiche del sistema di montaggio prima dell'acquisto. I pattern di montaggio VESA universali garantiscono ampia compatibilità con i display, mentre le piastre adattatrici offrono opzioni per apparecchiature specializzate o obsolete.

Quali operazioni di manutenzione sono necessarie per i supporti monitor a molla a gas?

La pulizia regolare con disinfettanti approvati per uso ospedaliero mantiene gli standard igienici senza compromettere le prestazioni meccaniche. Ispezioni periodiche dei meccanismi di regolazione e dei punti di fissaggio consentono di individuare precocemente eventuali problemi. I sistemi di qualità richiedono una manutenzione minima grazie a camere a gas sigillate e design avanzato dei cuscinetti, resistenti alla contaminazione e progettati per una lunga durata.

Questi sistemi di montaggio possono essere spostati da un carrello medico a un altro?

Sì, i sistemi professionali di montaggio sono dotati di meccanismi di bloccaggio senza utensili che consentono un'installazione e rimozione rapida senza modifiche permanenti alle strutture dei carrelli. Questa flessibilità permette alle strutture mediche di riconfigurare le assegnazioni delle attrezzature o spostare i sistemi di montaggio in base alle esigenze operative. L'imbottitura protettiva evita danni alle finiture dei carrelli durante le operazioni di installazione e rimozione.

Indice

- Tecnologia avanzata a molle a gas per applicazioni mediche

- Vantaggi della Costruzione in Lega di Alluminio

- Considerazioni sul Design Ergonomico

- Caratteristiche di Installazione e Compatibilità

- Fattori di Manutenzione e Longevità

-

Domande Frequenti

- Quale capacità di carico devo aspettarmi da un supporto di qualità per monitor su carrello medico?

- Come faccio a garantire la compatibilità con il mio carrello medico esistente?

- Quali operazioni di manutenzione sono necessarie per i supporti monitor a molla a gas?

- Questi sistemi di montaggio possono essere spostati da un carrello medico a un altro?