Durability Standards in Industrial Monitor Brackets

Material Strength for Industrial Environments

The materials selected for industrial monitor brackets really matter when it comes to how long they'll last, particularly since these brackets face pretty harsh conditions across different sectors. Steel and aluminum are common picks because they hold up well against tough environments. Take steel for example its tensile strength sits around 400 to 500 MPa which makes it great for situations where heavy loads need support. Most brackets have to meet certain industry standards such as ISO or ASTM specifications. These standards basically check that the materials can handle what's asked of them in real world settings. When manufacturers follow these guidelines, they're not just保证ing good quality materials but giving customers peace of mind knowing their equipment will keep working reliably even after years of hard use.

Incorporating materials with proven strength and adhering to stringent standards like ISO and ASTM can significantly enhance the functionality and lifespan of industrial monitor brackets, making them a vital component in the industrial sector where consistent performance is needed.

Testing Protocols for Harsh Conditions

Industrial monitor brackets undergo tough testing to prove they can handle rough conditions and last over time. Testing includes checking how well they resist temperature extremes both hot and cold, seeing if they hold up against rust in damp environments, and putting weight on them to make sure they won't break under pressure. When manufacturers simulate these harsh situations, it shows just how long these brackets will actually last before needing replacement. Most companies follow industry standards for quality control, so passing these tests means the brackets meet accepted safety requirements and perform reliably in real world settings where equipment failures could cause serious problems.

Certification from authoritative bodies further reinforces the credibility of these brackets, demonstrating their tested resilience. It's essential to align testing protocols with real-world scenarios to ensure consistent reliability across multiple industrial applications. Through recognized testing, manufacturers can guarantee the reliability of their products even in the harshest conditions.

Longevity Compared to Consumer-Grade Brackets

Industrial monitor brackets generally last much longer than what we see with consumer grade stuff, which makes them worth considering for business environments. Take a look at actual numbers industrial models tend to stick around twice as long as their cheaper counterparts before needing replacement. That means companies spend less money on replacements and face minimal interruptions during operations. Sure, these industrial options come with a bigger price tag upfront, but think about it this way most businesses will save plenty in the long run since they don't have to keep buying new brackets every few months. The math works out pretty well when looking at overall costs across several years of operation.

Testimonials from businesses highlight the practical benefits of using industrial monitor brackets, noting increased efficiency and decreased operational interruptions thanks to their enhanced durability. Making a switch to industrial-grade options not only improves longevity but offers a clear financial benefit through reduced total ownership costs.

Design Flexibility for Diverse Industrial Environments

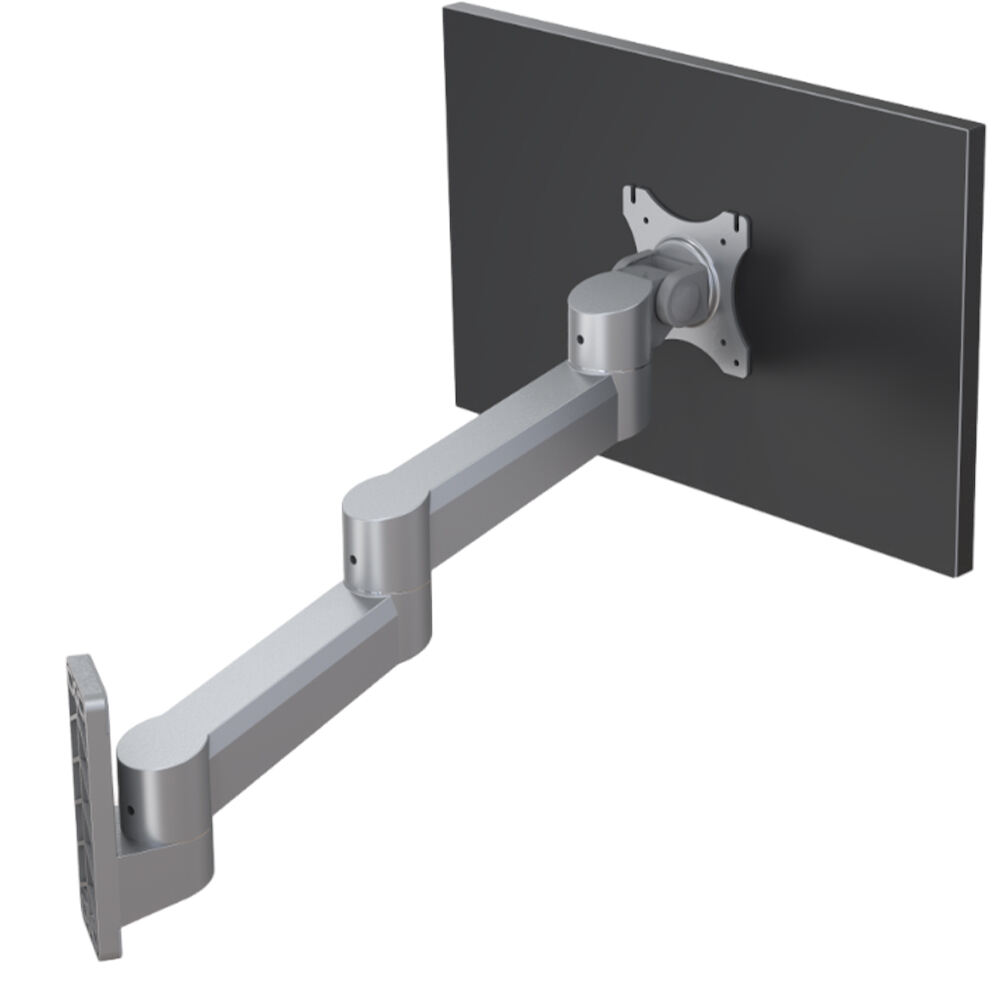

Adjustability for Ergonomic Workstations

Adjustable monitor brackets matter a lot in industrial workplaces when it comes to making things more ergonomic and comfortable for workers. Most good quality brackets let people tilt screens forward or backward, rotate them side to side, and move them up or down depending on what feels right. Real world testing shows that these adjustments can cut down on back pain and neck strain problems that happen from sitting all day at fixed positions. Factory managers who've implemented adjustable setups report fewer sick days related to repetitive strain injuries and better focus from their staff throughout shifts. For companies looking to keep their workforce healthy while boosting output, investing in proper monitor bracket systems isn't just nice to have anymore.

Customization in Hazardous Locations

When it comes to monitor bracket design for dangerous settings like chemical processing facilities or locations exposed to intense heat, customization isn't just nice to have—it's absolutely essential. These environments demand materials and construction methods that meet strict safety codes while keeping workers protected and operations running smoothly. Take stainless steel brackets with PTFE coatings as one practical solution. They fight off corrosion from aggressive chemicals and hold up against temps that would melt standard plastics. The whole point here is compliance with OSHA standards and other regulatory requirements, but beyond that, customized brackets solve real problems on site. A plant manager dealing with sulfuric acid exposure knows firsthand how critical these specialized components become in preventing equipment failure and workplace accidents.

Multi-Monitor Configurations for Control Rooms

Putting multiple monitors in control rooms really boosts what operators can see and how fast they react, giving companies working with live data a competitive advantage. The right industrial brackets for these setups help everything fit together smoothly and position screens where workers need them most. Some studies show around 25% better response times when folks have several screens to work with, which means operators get through their tasks quicker and actually know what's going on before making calls. Logistics centers, factories on assembly lines, and power plants all find these multi-screen arrangements super helpful. That's why it matters so much to have brackets and mounts that adapt to different spaces since every operation has its own unique layout challenges.

Vibration Resistance in Heavy Machinery Applications

Dampening Technologies for Manufacturing Floors

Putting dampening tech into monitor brackets really matters when dealing with all those constant vibrations found on manufacturing floors everywhere. These little shakes and tremors actually mess with how well electronics work over time, causing them to fail more often and costing companies serious money in downtime. Some research from last year showed that factories using better damping solutions saw around 40% fewer problems with their monitors. Take auto plants for instance they've been installing these vibration control systems for years now. The payoff? Their screens stay put longer without getting damaged during production runs. Nobody wants to deal with a broken display mid-shift when thousands of dollars worth of parts are waiting to be assembled.

Stability in Mining and Oil Rig Setups

The mining and oil rig industries face some pretty brutal operating conditions. Equipment stability often makes or breaks operations in these settings. The monitor brackets made specifically for such harsh environments include several sturdy design elements that keep screens firmly in place even when dealing with strong winds, constant vibrations from machinery, and occasional impacts from heavy tools or materials. Industry insiders know all too well what happens when inferior brackets are used instead. Failure rates jump through the roof, causing major disruptions in workflow and creating serious safety hazards on site. Many companies across both sectors have seen real improvements after switching to better quality brackets. Not only does this lead to smoother day-to-day operations, but it also cuts down significantly on the frequency of damaged equipment parts that need replacing.

Case Studies: Automotive Assembly Line Successes

Adding vibration resistant monitor brackets to automotive assembly lines really boosts how well operations run day to day. Take Ford's plant in Michigan as an example they saw downtime drop by about 30% after switching to these special mounts that absorb machine vibrations. The workers noticed things ran smoother too since screens stayed stable even during heavy machinery work. What makes this so valuable is that it cuts down on those frustrating stoppages when displays get knocked out of alignment. For other factories dealing with similar issues, especially in manufacturing sectors where equipment constantly moves around, investing in good quality mounting solutions pays off big time in both productivity gains and reduced repair bills over the long haul.

Steel vs. Aluminum: Performance Tradeoffs

Performance Tradeoffs

Picking between steel and aluminum for monitor brackets really comes down to what matters most in any given situation. Steel has got that edge when it comes to strength and lasting power, so it works great for situations where the bracket needs to hold up something really heavy without bending or breaking over time. The downside? Steel weighs a lot more than aluminum does, plus it usually costs more too. Aluminum on the other hand is much lighter weight, which makes the whole setup easier to handle during installation and keeps things from feeling too bulky. But there's a catch here as well. While aluminum handles normal loads just fine, it simply doesn't stand up to extreme weights like steel can. Most people find themselves weighing these factors based on their specific needs rather than going strictly by specs alone.

When it comes to how much weight they can hold, studies indicate steel brackets are great for supporting bigger screens without bending or warping. But aluminum actually handles stress better in the long run, which means it doesn't wear out as quickly. Most engineers we've talked to agree that picking between these materials really depends on what the project needs. For installations where strength matters most and nobody cares about extra pounds, steel makes sense. On the flip side, aluminum tends to be the go to choice when things need to be moved around regularly or when budget is a concern. The price difference alone often sways decisions in favor of aluminum for many applications.

Weight Distribution for Large-Format Displays

Getting the weight distribution right matters a lot when creating monitor brackets for those big screen displays because this affects whether or not they meet safety standards. If the weight isn't spread out properly, there's a real danger of the whole thing tipping over which could damage expensive equipment and put people nearby at risk too. Good bracket design usually includes some kind of balance system that spreads the load throughout the bracket itself rather than concentrating all the weight in one spot. Most manufacturers will tell us this approach cuts down on accident risks while still allowing for sturdy installation. Some even go so far as to include extra reinforcement points where stress tends to build up during normal use conditions.

Good design for monitor mounts really needs several support points plus adjustable parts so they can handle different screen sizes without tipping over. Industrial safety rules from places like OSHA stress how important it is for brackets to have solid mounting systems that can actually hold up under the weight they're supposed to carry. When companies follow these guidelines properly, their equipment meets what's needed for day to day use and stays within legal safety boundaries too. This helps avoid accidents and keeps insurance costs from going through the roof.

Impact of Load Capacity on Safety Compliance

The load capacity specs really matter when it comes to keeping workplaces safe. After all, these numbers tell us exactly how much weight a monitor bracket can handle before things start getting dangerous. When someone ignores those limits, what usually happens? Equipment fails, screens crash down, and people get hurt. That's why sticking to guidelines from organizations like OSHA isn't just good practice—it's essential. Workers need brackets that actually match what they'll be supporting day to day. A 20 lb bracket won't cut it if monitors plus accessories tip the scales at 35 lbs. Getting this right prevents accidents and keeps operations running smoothly.

Most building codes require monitor brackets to meet certain weight limits to prevent accidents when equipment fails. Smart installers always check what their monitors actually weigh before picking a bracket. Going for something rated higher than needed isn't just good practice it's practically essential for keeping things safe long term. When brackets are properly matched to their load, they last much longer without warping or breaking. Displays stay secure too, which means fewer replacements and repair bills down the road. Many office managers find this approach pays for itself within a year through reduced downtime and replacement costs.

Industry-Specific Bracket Solutions

Manufacturing: Real-Time Process Monitoring

Bracket systems have become pretty important in manufacturing for keeping tabs on processes as they happen. These brackets hold up those big industrial screens where workers see all sorts of vital information right away. Factories actually run better when everyone can spot problems fast because they don't waste time guessing what's wrong. Take one car plant for instance they installed these special mounts for their monitors across the assembly lines. The result? Fewer stoppages and way less money lost waiting around for someone to figure out what went wrong. Workers just glance at the screens and know exactly what needs fixing before things get too bad.

Energy Sector: Ruggedized Brackets for Outdoor Use

In the energy industry, ruggedized brackets play a critical role when dealing with devices exposed to tough outdoor conditions. Built to handle whatever Mother Nature throws at them, these brackets help cut down on equipment failures during storms or temperature extremes. Take oil and gas fields as an example. Here, ruggedized brackets keep monitoring gear working properly even after months of exposure. The result? Longer lasting systems that don't need constant repairs, which saves money in the long run for companies operating in these challenging environments.

Transportation: Vibration-Proof Rail Network Installations

For rail systems across the transportation world, those special vibration resistant mounts really make all the difference. When equipment gets mounted wrong on trains or tracks, things start breaking down more often and repairs pile up fast. Take that major commuter line in Chicago last year they switched out their old mounting hardware for these new shock absorbing brackets. The difference was night and day fewer breakdowns during rush hour commutes and mechanics spending less time fixing screens that kept getting knocked loose. These mounts actually hold up against the constant jostling from train movements, so operators don't have to worry about displays going haywire every time there's a curve in the track. Most rail companies now see these specialized brackets as essential gear rather than just another optional upgrade.

Healthcare: Sterilizable Brackets for Surgical Suites

When it comes to hospitals and operating rooms specifically, the needs for monitor brackets that can be sterilized are quite different from regular office equipment. Keeping things clean is absolutely essential here since even tiny amounts of bacteria can cause serious problems during surgeries. The brackets need to meet all sorts of strict rules set by organizations like the CDC and FDA regarding how medical devices should work and look. Most modern bracket systems now use materials that withstand repeated autoclaving without breaking down, which helps maintain sterility between procedures. These specialized mounts not only comply with infection control protocols but also hold monitors securely where surgeons need them most during operations.

FAQ

What materials are best for industrial monitor brackets?

High-grade metals like steel and aluminum are preferred due to their robustness and ability to withstand tough industrial environments.

Why are testing protocols important for monitor brackets?

Testing protocols ensure the resilience and longevity of industrial monitor brackets by simulating harsh conditions. This helps validate the product's lifespan and performance capability.

How do industrial monitor brackets compare to consumer-grade products?

Industrial monitor brackets typically have a longer lifespan, offering superior durability and fewer replacements, which leads to reduced downtime.

What factors should be considered for bracket design in hazardous locations?

Customization, specialized materials, and compliance with safety standards are key factors in designing brackets for hazardous environments.

How do dampening technologies benefit manufacturing floors?

They reduce vibrations that compromise the performance and longevity of electronic equipment, minimizing risks of failures and downtime.

Why is weight distribution crucial for large-format displays?

Proper weight distribution minimizes the risk of tipping hazards, ensuring safety and compliance in industrial settings.

Table of Contents

- Durability Standards in Industrial Monitor Brackets

- Design Flexibility for Diverse Industrial Environments

- Vibration Resistance in Heavy Machinery Applications

- Steel vs. Aluminum: Performance Tradeoffs

- Industry-Specific Bracket Solutions

-

FAQ

- What materials are best for industrial monitor brackets?

- Why are testing protocols important for monitor brackets?

- How do industrial monitor brackets compare to consumer-grade products?

- What factors should be considered for bracket design in hazardous locations?

- How do dampening technologies benefit manufacturing floors?

- Why is weight distribution crucial for large-format displays?