มาตรฐานความทนทานในตัวยึดจอภาพอุตสาหกรรม

ความแข็งแรงของวัสดุสำหรับสภาพแวดล้อมอุตสาหกรรม

วัสดุที่เลือกใช้สำหรับราวจับหน้าจออุตสาหกรรมมีความสำคัญอย่างมากต่ออายุการใช้งาน เนื่องจากราวจับเหล่านี้ต้องทำงานภายใต้สภาพแวดล้อมที่ค่อนข้างรุนแรงในหลายอุตสาหกรรม วัสดุที่นิยมใช้กันคือเหล็กและอลูมิเนียม เนื่องจากมีความทนทานต่อสภาพแวดล้อมที่ท้าทาย ตัวอย่างเช่น เหล็กมีความแข็งแรงแรงดึงอยู่ระหว่าง 400 ถึง 500 เมกะปาสคาล ซึ่งทำให้เหมาะสำหรับสถานการณ์ที่ต้องรับน้ำหนักมาก การสนับสนุน . ราวจับส่วนใหญ่จำเป็นต้องเป็นไปตามมาตรฐานอุตสาหกรรมที่กำหนด เช่น มาตรฐาน ISO หรือ ASTM มาตรฐานเหล่านี้จะช่วยตรวจสอบว่าวัสดุที่ใช้มีความสามารถเพียงพอที่จะรับมือกับการใช้งานจริงในสภาพแวดล้อมต่าง ๆ เมื่อผู้ผลิตปฏิบัติตามแนวทางเหล่านี้ พวกเขาไม่เพียงแค่รับประกันคุณภาพของวัสดุที่ดี แต่ยังมอบความอุ่นใจให้แก่ลูกค้า ด้วยการให้ความมั่นใจว่าอุปกรณ์จะยังคงทำงานได้อย่างเชื่อถือได้ แม้จะผ่านการใช้งานอย่างหนักมานานหลายปี

การนำวัสดุที่มีความแข็งแรงพิสูจน์แล้วมาใช้ พร้อมทั้งปฏิบัติตามมาตรฐานที่เข้มงวดอย่าง ISO และ ASTM สามารถเพิ่มประสิทธิภาพและการใช้งานที่ยาวนานของตะขอสำหรับจอภาพอุตสาหกรรม ทำให้มันกลายเป็นองค์ประกอบสำคัญในภาคอุตสาหกรรม ที่ซึ่งการดำเนินงานที่สม่ำเสมอจำเป็นต้องเกิดขึ้น

โปรโตคอลการทดสอบในสภาวะที่รุนแรง

ตัวยึดสำหรับจอภาพอุตสาหกรรมจะต้องผ่านการทดสอบที่เข้มงวด เพื่อพิสูจน์ว่าสามารถทนต่อสภาพแวดล้อมที่เลวร้ายและใช้งานได้ยาวนานตามเวลาที่กำหนด การทดสอบรวมถึงการตรวจสอบว่าตัวยึดสามารถทนต่ออุณหภูมิที่สูงและต่ำได้ดีเพียงใด ทดสอบการทนต่อสนิมในสภาพแวดล้อมที่ชื้นแฉะ รวมถึงการทดสอบโดยการวางน้ำหนักบนตัวยึดเพื่อให้แน่ใจว่าจะไม่หักหรือเสียหายเมื่ออยู่ภายใต้แรงกดดัน เมื่อผู้ผลิตจำลองสถานการณ์ที่โหดร้ายเหล่านี้ จะสามารถบ่งชี้ได้ว่าตัวยึดเหล่านี้สามารถใช้งานได้ยาวนานเพียงใดก่อนที่จะต้องเปลี่ยนใหม่ บริษัทส่วนใหญ่ปฏิบัติตามมาตรฐานอุตสาหกรรมในด้านการควบคุมคุณภาพ ดังนั้นการผ่านการทดสอบเหล่านี้แสดงว่าตัวยึดดังกล่าวมีคุณสมบัติที่เป็นไปตามข้อกำหนดด้านความปลอดภัยที่ยอมรับกันโดยทั่วไป และสามารถทำงานได้อย่างเชื่อถือได้ในสภาพการใช้งานจริง ซึ่งการเกิดความล้มเหลวของอุปกรณ์อาจก่อให้เกิดปัญหาร้ายแรงตามมา

การรับรองจากองค์กรที่มีอำนาจช่วยเสริมสร้างความน่าเชื่อถือของตัวยึดเหล่านี้ แสดงให้เห็นถึงความทนทานที่ผ่านการทดสอบแล้ว เป็นเรื่องสำคัญที่จะต้องกำหนดให้โปรโตคอลการทดสอบตรงกับสถานการณ์จริง เพื่อให้มั่นใจถึงความน่าเชื่อถือที่สม่ำเสมอในหลาย ๆ การประยุกต์ใช้งานทางอุตสาหกรรม ด้วยการทดสอบที่เป็นที่ยอมรับ ผู้ผลิตสามารถรับประกันความน่าเชื่อถือของ ผลิตภัณฑ์ แม้ในสภาวะที่เลวร้ายที่สุด

อายุการใช้งานที่ยาวนานเมื่อเทียบกับตัวยึดสำหรับผู้บริโภคทั่วไป

ตัวยึดจอภาพอุตสาหกรรมโดยทั่วไปมีอายุการใช้งานที่ยาวนานกว่าอุปกรณ์ทั่วไปที่เราเห็นในท้องตลาดมาก ซึ่งทำให้เหมาะสำหรับนำไปใช้ในสภาพแวดล้อมทางธุรกิจ พิจารณาจากตัวเลขจริง โมเดลอุตสาหกรรมมักจะมีอายุการใช้งานยาวนานกว่ารุ่นทั่วไปถึงสองเท่าก่อนที่จะต้องเปลี่ยนใหม่ นั่นหมายความว่าบริษัทสามารถประหยัดค่าใช้จ่ายในการเปลี่ยนอุปกรณ์ใหม่ และลดการหยุดชะงักในการดำเนินงานได้ แน่นอนว่าตัวเลือกอุตสาหกรรมเหล่านี้มีราคาเริ่มต้นที่สูงกว่า แต่ลองคิดดูอีกมุมหนึ่งว่า ธุรกิจส่วนใหญ่จะประหยัดเงินได้มากในระยะยาว เพราะไม่จำเป็นต้องซื้ออุปกรณ์ใหม่ทุกๆ ไม่กี่เดือน การคำนวณค่าใช้จ่ายโดยรวมในระยะหลายปีของการใช้งานจึงคุ้มค่ามากกว่า

คำรับรองจากธุรกิจต่างๆ แสดงถึงประโยชน์ในการใช้งานจริงของการใช้ตัวยึดจอภาพอุตสาหกรรม โดยระบุถึงประสิทธิภาพการทำงานที่เพิ่มขึ้นและการหยุดชะงักในการดำเนินงานลดลง เนื่องจากความทนทานที่เพิ่มขึ้น การเปลี่ยนมาใช้ตัวยึดเกรดอุตสาหกรรมไม่เพียงแค่เพิ่มอายุการใช้งาน แต่ยังมอบประโยชน์ทางการเงินที่ชัดเจนจากการลดต้นทุนตลอดอายุการใช้งาน

ความยืดหยุ่นในการออกแบบเพื่อรองรับสภาพแวดล้อมอุตสาหกรรมที่หลากหลาย

ความสามารถในการปรับตั้งค่าเพื่อสร้างสถานีทำงานที่เหมาะสมตามหลักสรีรศาสตร์

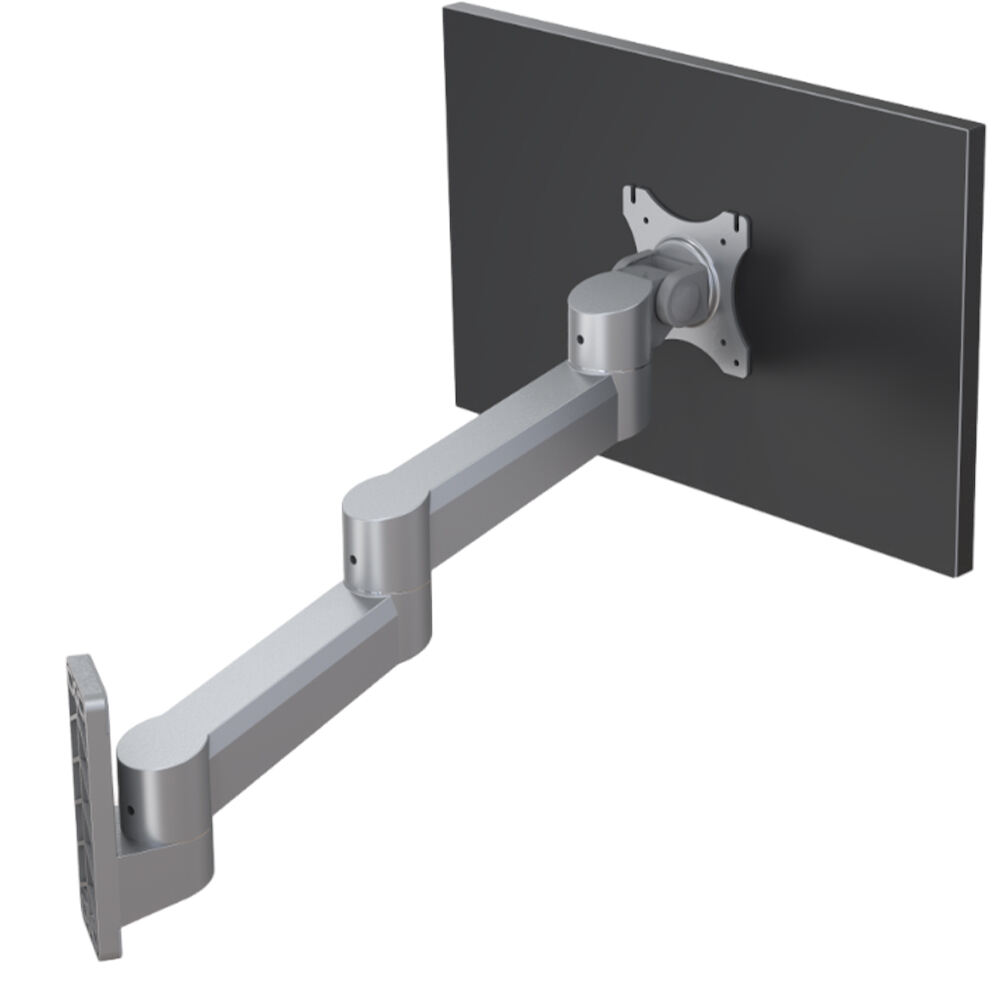

ตัวยึดจอภาพที่ปรับระดับได้มีความสำคัญมากในสถานที่ทำงานอุตสาหกรรม เมื่อต้องการทำให้สภาพแวดล้อมการทำงานมีความเหมาะสมและสะดวกสบายมากขึ้นสำหรับพนักงาน ตัวยึดคุณภาพดีส่วนใหญ่ช่วยให้ผู้ใช้สามารถปรับเอียงหน้าจอไปข้างหน้าหรือข้างหลัง หมุนซ้ายขวา และเลื่อนขึ้นลงได้ตามที่รู้สึกว่าเหมาะสมที่สุด การทดสอบจริงแสดงให้เห็นว่าการปรับระดับเหล่านี้สามารถช่วยลดปัญหาปวดหลังและเมื่อยล้าบริเวณคอที่เกิดจากการนั่งอยู่ในท่าเดิมตลอดทั้งวันได้ ผู้จัดการโรงงานที่นำระบบที่ปรับระดับได้ไปใช้รายงานว่า จำนวนวันลาป่วยที่เกี่ยวข้องกับอาการบาดเจ็บจากแรงงานซ้ำซ้อนลดลง และพนักงานมีสมาธิในการทำงานตลอดช่วงเวลามากขึ้น สำหรับบริษัทที่ต้องการรักษาสุขภาพของแรงงานให้แข็งแรงพร้อมทั้งเพิ่มผลผลิต การลงทุนในระบบตัวยึดจอภาพที่เหมาะสมจึงไม่ใช่เรื่องที่เพียงแค่ต้องการเท่านั้น แต่เป็นสิ่งจำเป็น

การปรับแต่งสำหรับพื้นที่อันตราย

เมื่อพูดถึงการออกแบบราวจับจอภาพสำหรับสถานที่เสี่ยงอันตราย เช่น โรงงานแปรรูปสารเคมี หรือพื้นที่ที่มีความร้อนสูง การปรับแต่งไม่ใช่แค่เรื่องที่ดีถ้ามี แต่เป็นสิ่งจำเป็นอย่างยิ่ง สภาพแวดล้อมเหล่านี้ต้องการวัสดุและวิธีการก่อสร้างที่สอดคล้องกับมาตรฐานความปลอดภัยที่เข้มงวด ขณะเดียวกันก็ช่วยปกป้องผู้ปฏิบัติงานและทำให้การดำเนินงานเป็นไปอย่างราบรื่น ตัวอย่างเช่น ราวจับจากสแตนเลสสตีลเคลือบด้วยสาร PTFE เป็นหนึ่งในทางแก้ปัญหาที่ใช้งานได้จริง ซึ่งสามารถต้านทานการกัดกินจากสารเคมีที่รุนแรง และทนต่ออุณหภูมิที่สูงจนพลาสติกทั่วไปละลายได้ จุดประสงค์หลักคือการปฏิบัติตามมาตรฐานของ OSHA และข้อกำหนดตามกฎหมายอื่น ๆ แต่ยิ่งไปกว่านั้น ราวจับแบบปรับแต่งสามารถแก้ปัญหาเฉพาะหน้างานได้จริง ผู้จัดการโรงงานที่ต้องเผชิญกับการสัมผักรวมถึงกรดซัลฟูริกย่อมทราบดีว่าองค์ประกอบเฉพาะทางเหล่านี้มีบทบาทสำคัญเพียงใดในการป้องกันการเกิดความล้มเหลวของอุปกรณ์และอุบัติเหตุในสถานที่ทำงาน

การติดตั้งจอภาพหลายจอสำหรับห้องควบคุม

การติดตั้งจอภาพหลายจอในห้องควบคุมสามารถเพิ่มประสิทธิภาพในการมองเห็นและอัตราการตอบสนองของผู้ควบคุมเครื่องมือ ซึ่งเป็นประโยชน์ต่อองค์กรที่ทำงานกับข้อมูลแบบเรียลไทม์ให้ได้เปรียบในการแข่งขัน ชุดอุปกรณ์ยึดจับสำหรับอุตสาหกรรมที่เหมาะสมกับการติดตั้งแบบนี้ จะช่วยให้ทุกอย่างประกอบเข้าด้วยกันได้อย่างราบรื่น และปรับตั้งตำแหน่งจอภาพให้ตรงกับพื้นที่ที่พนักงานต้องการมากที่สุด มีงานวิจัยบางชิ้นแสดงให้เห็นว่าเวลาตอบสนองดีขึ้นประมาณ 25% เมื่อบุคคลมีจอภาพหลายจอให้ใช้งาน ซึ่งหมายความว่าผู้ควบคุมสามารถทำงานได้รวดเร็วขึ้น และเข้าใจสถานการณ์โดยรวมได้ดีขึ้นก่อนตัดสินใจโทรแจ้ง ศูนย์โลจิสติกส์ โรงงานที่ใช้สายพานลำเลียง และโรงไฟฟ้าต่างพบว่าการจัดวางจอภาพหลายจอเป็นประโยชน์อย่างมาก นั่นจึงเป็นเหตุผลว่าทำไมการมีชุดอุปกรณ์ยึดและติดตั้งที่ปรับให้เข้ากับพื้นที่ต่างๆ ได้จึงสำคัญมาก เนื่องจากแต่ละพื้นที่ปฏิบัติงานมีข้อจำกัดด้านการจัดวางที่แตกต่างกันออกไป

ความต้านทานต่อการสั่นสะเทือนในเครื่องจักรขนาดใหญ่

เทคโนโลยีการลดแรงสะเทือนสำหรับพื้นที่การผลิต

การนำเทคโนโลยีการดูดซับแรงสะเทือนมาใช้กับตัวยึดจอภาพมีความสำคัญมากเมื่อต้องรับมือกับการสั่นสะเทือนที่เกิดขึ้นอย่างต่อเนื่องในโรงงานอุตสาหกรรมทั่วไป การสั่นเล็กน้อยเหล่านี้สามารถรบกวนการทำงานของอุปกรณ์อิเล็กทรอนิกส์ในระยะยาว ทำให้อุปกรณ์เกิดความเสียหายบ่อยขึ้นและสร้างความเสียหายทางเศรษฐกิจมหาศาลให้กับบริษัทจากช่วงเวลาที่ไม่สามารถดำเนินการผลิตได้ จากการวิจัยเมื่อปีที่แล้วพบว่าโรงงานที่ใช้เทคโนโลยีการดูดซับแรงสั่นสะเทือนที่มีประสิทธิภาพมากขึ้น พบว่าปัญหาเกี่ยวกับจอภาพลดลงประมาณ 40% ยกตัวอย่างเช่นโรงงานประกอบรถยนต์ที่ติดตั้งระบบควบคุมการสั่นสะเทือนเหล่านี้มานานหลายปีแล้ว ผลลัพธ์ที่ได้คือ หน้าจอยังคงใช้งานได้ดีโดยไม่เสียหายระหว่างกระบวนการผลิต ไม่มีใครอยากเจอปัญหาหน้าจอพังกลางชิฟท์งาน ขณะที่ชิ้นส่วนมูลค่าหลายพันดอลลาร์กำลังรอการประกอบอยู่

ความเสถียรในสถานประกอบการเหมืองแร่และแท่นขุดเจาะน้ำมัน

อุตสาหกรรมเหมืองแร่และแท่นขุดเจาะน้ำมันต้องเผชิญกับสภาพการใช้งานที่ค่อนข้างโหดร้าย ความเสถียรของอุปกรณ์มักเป็นตัวแปรสำคัญที่กำหนดความสำเร็จหรือล้มเหลวของการดำเนินงานในสภาพแวดล้อมเหล่านี้ ที่ยึดจอภาพที่ออกแบบมาโดยเฉพาะสำหรับสภาพแวดล้อมที่ท้าทายนี้ มีองค์ประกอบการออกแบบที่แข็งแรงทนทานหลายอย่าง ซึ่งช่วยให้จอภาพยึดติดอยู่กับที่ได้อย่างมั่นคง แม้จะต้องเผชิญกับลมแรง แรงสั่นสะเทือนอย่างต่อเนื่องจากเครื่องจักร และบางครั้งก็มีแรงกระแทกจากเครื่องมือหรือวัสดุหนักๆ ผู้ที่อยู่ในอุตสาหกรรมนี้ล้วนรู้ดีว่าจะเกิดอะไรขึ้นหากเลือกใช้ที่ยึดคุณภาพต่ำกว่ามาตรฐาน พบว่าอัตราการเกิดความล้มเหลวเพิ่มขึ้นสูงมาก ส่งผลให้เกิดการหยุดชะงักอย่างรุนแรงในกระบวนการทำงาน และสร้างความเสี่ยงด้านความปลอดภัยที่ร้ายแรงบนพื้นที่ปฏิบัติงาน บริษัทหลายแห่งในทั้งสองภาคส่วนต่างเห็นการปรับปรุงที่ชัดเจนหลังจากเปลี่ยนมาใช้ที่ยึดคุณภาพสูงกว่า ไม่เพียงแต่ช่วยให้การดำเนินงานในแต่ละวันเป็นไปอย่างราบรื่นขึ้นเท่านั้น แต่ยังลดความถี่ในการเปลี่ยนชิ้นส่วนอุปกรณ์ที่เสียหายอย่างมีนัยสำคัญอีกด้วย

กรณีศึกษา: ความสำเร็จบนสายการประกอบรถยนต์

การเพิ่มชุดยึดจอภาพที่สามารถกันการสั่นสะเทือนเข้าไปในสายการประกอบยานยนต์นั้น ช่วยเพิ่มประสิทธิภาพในการดำเนินงานประจำวันได้อย่างชัดเจน ตัวอย่างเช่น โรงงานของ Ford ในรัฐมิชิแกน ซึ่งหลังจากเปลี่ยนมาใช้ชุดยึดพิเศษที่สามารถดูดซับการสั่นสะเทือนของเครื่องจักรแล้ว พบว่าเวลาหยุดทำงานลดลงประมาณ 30% พนักงานยังสังเกตได้อีกว่าการทำงานราบรื่นขึ้นด้วย เนื่องจากหน้าจอภาพยังคงอยู่ในสภาพเสถียรแม้ในขณะที่เครื่องจักรขนาดใหญ่กำลังทำงานหนัก สิ่งที่ทำให้เรื่องนี้มีคุณค่ามากก็คือ มันช่วยลดการหยุดชะงักที่สร้างความหงุดหงิด ซึ่งเกิดขึ้นเมื่อหน้าจอถูกสั่นกระทบจนปรับแนวไม่อยู่ สำหรับโรงงานอื่น ๆ ที่เผชิญกับปัญหาลักษณะเดียวกัน โดยเฉพาะในภาคการผลิตที่อุปกรณ์ต้องทำงานเคลื่อนไหวตลอดเวลา การลงทุนในทางแก้ปัญหาการติดตั้งที่มีคุณภาพดีนั้น ให้ผลตอบแทนที่คุ้มค่าในระยะยาว ทั้งในแง่ของประสิทธิภาพในการผลิตที่เพิ่มขึ้น และค่าใช้จ่ายในการซ่อมแซมที่ลดลง

เหล็ก VS. อลูมิเนียม: การเปรียบเทียบสมรรถนะ

การเปรียบเทียบสมรรถนะ

การเลือกระหว่างเหล็กกับอลูมิเนียมสำหรับราวจับจอภาพนั้น สุดท้ายแล้วขึ้นอยู่กับสิ่งที่สำคัญที่สุดในแต่ละสถานการณ์เป็นหลัก เหล็กมีความเหนียวและทนทานกว่า ทำให้เหมาะสำหรับการใช้งานที่ต้องรับน้ำหนักมากโดยไม่เกิดการงอหรือแตกหักตามกาลเวลา แต่จุดด้อยของเหล็กคือมีน้ำหนักมากกว่าอลูมิเนียม และมักมีราคาสูงกว่าด้วย ในทางกลับกัน อลูมิเนียมมีน้ำหนักเบา ทำให้การติดตั้งจัดการง่ายและไม่รู้สึกหนักเกินไป แต่ก็มีข้อเสียเช่นกัน แม้อลูมิเนียมจะรับน้ำหนักทั่วไปได้ดี แต่เมื่อเจอแรงกดดันจากน้ำหนักมหาศาลแล้ว ย่อมสู้เหล็กไม่ได้ ผู้คนส่วนใหญ่จึงพิจารณาเลือกจากปัจจัยเหล่านี้โดยคำนึงถึงความต้องการเฉพาะของตนเอง มากกว่าจะพิจารณาเพียงแค่ข้อมูลทางเทคนิคเพียงอย่างเดียว

เมื่อพูดถึงน้ำหนักที่สามารถรับได้ งานวิจัยชี้ว่า ตัวยึดแบบเหล็กกล้าเหมาะสำหรับการรองรับหน้าจอขนาดใหญ่โดยไม่เกิดการงอหรือบิดงอ แต่ในระยะยาวอลูมิเนียมกลับรับแรงกระทำได้ดีกว่า ซึ่งหมายความว่าจะสึกหรอช้ากว่า วิศวกรที่เราได้พูดคุยด้วยส่วนใหญ่เห็นพ้องว่า การเลือกวัสดุทั้งสองชนิดนี้ขึ้นอยู่กับความต้องการของโครงการเป็นหลัก สำหรับการติดตั้งที่เน้นความแข็งแรงเป็นสำคัญ และไม่มีใครสนใจเรื่องน้ำหนักเพิ่มเติม เหล็กกล้าจึงเป็นตัวเลือกที่เหมาะสม ในทางกลับกัน อลูมิเนียมมักเป็นวัสดุที่เลือกใช้เมื่อจำเป็นต้องเคลื่อนย้ายเป็นประจำ หรือเมื่อต้องคำนึงถึงงบประมาณ ความแตกต่างของราคาเพียงอย่างเดียวก็มักเป็นตัวแปรสำคัญที่ทำให้ตัดสินใจเลือกอลูมิเนียมในหลาย ๆ การใช้งาน

การกระจายแรงน้ำหนักสำหรับจอภาพแบบ Large-Format

การกระจายแรงดันน้ำหนักให้ถูกต้องมีความสำคัญมากเมื่อต้องออกแบบตัวยึดสำหรับจอภาพขนาดใหญ่ เพราะสิ่งนี้มีผลต่อการปฏิบัติตามมาตรฐานความปลอดภัย หากน้ำหนักไม่ถูกกระจายอย่างเหมาะสม ก็มีความเสี่ยงอย่างมากที่อุปกรณ์ทั้งชุดอาจพลิกคว่ำ ซึ่งอาจทำให้เกิดความเสียหายกับอุปกรณ์ราคาแพง และเป็นอันตรายต่อบุคคลที่อยู่ใกล้เคียงด้วย โดยทั่วไปแล้วการออกแบบตัวยึดที่ดีมักจะรวมระบบทดเทียมแรงดันเข้าไว้ด้วย เพื่อกระจายแรงที่รับน้ำหนักไปยังส่วนต่างๆ ของตัวยึดเอง แทนที่จะปล่อยให้น้ำหนักไปรวมตัวกันที่จุดใดจุดหนึ่ง ผู้ผลิตส่วนใหญ่ระบุว่าวิธีการนี้ช่วยลดความเสี่ยงจากอุบัติเหตุ ขณะเดียวกันก็ยังคงความแข็งแรงในการติดตั้งไว้ได้ บางรายถึงขั้นเพิ่มจุดเสริมโครงสร้างพิเศษในบริเวณที่มักจะเกิดแรงสะสมขึ้นภายใต้สภาวะการใช้งานปกติ

การออกแบบที่ดีสำหรับขาตั้งจอภาพ จำเป็นต้องมีจุดยึดหลายจุดรวมถึงชิ้นส่วนที่ปรับระดับได้ เพื่อให้สามารถรองรับขนาดหน้าจอที่แตกต่างกันได้โดยไม่ล้มเอียง กฎความปลอดภัยอุตสาหกรรมจากองค์กรต่างๆ เช่น OSHA ให้ความสำคัญกับระบบการยึดติดตั้งของตัวราวีทีที่ต้องมีความแข็งแรงเพียงพอที่จะรับน้ำหนักที่กำหนดไว้จริง เมื่อบริษัทปฏิบัติตามแนวทางเหล่านี้อย่างถูกต้อง อุปกรณ์จะสามารถรองรับการใช้งานประจำวันและอยู่ในขอบเขตความปลอดภัยตามกฎหมาย ซึ่งช่วยลดอุบัติเหตุและป้องกันไม่ให้ค่าประกันภัยเพิ่มสูงขึ้นเกินจำเป็น

ผลกระทบของกำลังรับน้ำหนักต่อความสอดคล้องด้านความปลอดภัย

ข้อมูลจำเพาะด้านกำลังบรรทุกมีความสำคัญอย่างมากเมื่อพูดถึงการรักษาความปลอดภัยในสถานที่ทำงาน เพราะตัวเลขเหล่านี้บอกเราอย่างชัดเจนว่าราวจับจอภาพสามารถรับน้ำหนักได้มากแค่ไหนก่อนที่สถานการณ์จะเริ่มอันตราย เมื่อมีคนเพิกเฉยต่อข้อจำกัดเหล่านี้ มักจะเกิดอะไรขึ้น? อุปกรณ์เสียหาย หน้าจอหล่นพัง และคนได้รับบาดเจ็บ นั่นคือเหตุผลที่การยึดมั่นตามแนวทางขององค์กรต่างๆ เช่น OSHA ไม่ใช่แค่การปฏิบัติที่ดี แต่เป็นสิ่งจำเป็น พนักงานต้องการราวจับที่มีมาตรฐานตรงกับน้ำหนักที่พวกเขาต้องรองรับในแต่ละวัน ราวที่รับได้เพียง 20 ปอนด์ย่อมไม่เพียงพอหากหน้าจอบวกอุปกรณ์เสริมมีน้ำหนักถึง 35 ปอนด์ การคำนวณให้ถูกต้องแบบนี้ช่วยป้องกันอุบัติเหตุและทำให้การทำงานดำเนินไปอย่างราบรื่น

รหัสอาคารส่วนใหญ่กำหนดให้ต้องใช้ราวจับหน้าจอที่มีน้ำหนักตามเกณฑ์ที่กำหนด เพื่อป้องกันอุบัติเหตุในกรณีที่อุปกรณ์เกิดความเสียหาย ช่างติดตั้งที่มีความรู้ความเข้าใจจะตรวจสอบน้ำหนักที่แท้จริงของหน้าจอก่อนเลือกใช้ราวจับเสมอ การเลือกใช้ราวจับที่รองรับน้ำหนักได้มากกว่าที่จำเป็นไม่ใช่เพียงแค่แนวทางปฏิบัติที่ดี แต่ยังเป็นสิ่งจำเป็นอย่างยิ่งต่อการรักษาความปลอดภัยในระยะยาว เมื่อราวจับถูกเลือกให้เหมาะสมกับน้ำหนักที่ใช้งาน จะช่วยให้มีอายุการใช้งานที่ยาวนานขึ้นโดยไม่เกิดการบิดงอหรือแตกหัก หน้าจอก็จะยึดแน่นอยู่ตลอด ซึ่งหมายถึงการเปลี่ยนใหม่หรือซ่อมแซมที่ลดน้อยลงในอนาคต ผู้จัดการออฟฟิศหลายคนพบว่าวิธีนี้ช่วยประหยัดค่าใช้จ่ายจนคุ้มค่าภายในหนึ่งปี จากการลดเวลาที่ต้องหยุดใช้งานและค่าใช้จ่ายในการเปลี่ยนอุปกรณ์

โซลูชันแขนจับเฉพาะอุตสาหกรรม

การผลิต: การตรวจสอบกระบวนการแบบเรียลไทม์

ระบบติดตั้งแบบแบร็คเก็ตมีความสำคัญมากขึ้นในอุตสาหกรรมการผลิต เพื่อคอยตรวจสอบกระบวนการทำงานแบบเรียลไทม์ แบร็คเก็ตเหล่านี้ใช้สำหรับยึดจอภาพขนาดใหญ่ในโรงงานอุตสาหกรรมที่พนักงานสามารถมองเห็นข้อมูลสำคัญต่าง ๆ ได้ทันที การดำเนินงานของโรงงานจะมีประสิทธิภาพดียิ่งขึ้นเมื่อทุกคนสามารถสังเกตพบปัญหาได้อย่างรวดเร็ว เพราะไม่ต้องเสียเวลาเดาสาเหตุที่ผิดพลาด ตัวอย่างเช่น โรงงานประกอบรถยนต์แห่งหนึ่งได้ติดตั้งตัวยึดพิเศษสำหรับจอภาพไว้ตามสายการผลิต ผลลัพธ์คือการหยุดทำงานลดลง และเสียค่าใช้จ่ายน้อยลงจากการรอคอยให้ใครสักคนมาแก้ปัญหา พนักงานเพียงแค่มองไปที่หน้าจอ ก็สามารถทราบได้ทันทีว่าปัญหาใดต้องการการแก้ไขก่อนที่สถานการณ์จะแย่ลงไปอีก

ภาคพลังงาน: ตัวยึดสำหรับใช้ภายนอกที่ออกแบบมาให้มีความทนทาน

ในอุตสาหกรรมพลังงาน ชุดยึดที่ออกแบบมาให้ทนทานมีบทบาทสำคัญเมื่อต้องทำงานกับอุปกรณ์ที่ถูกใช้งานภายใต้สภาพแวดล้อมที่ยากลำบาก โครงสร้างเหล่านี้ถูกสร้างมาเพื่อรองรับทุกสิ่งที่ธรรมชาติท้าทายพวกมัน ซึ่งช่วยลดปัญหาความล้มเหลวของอุปกรณ์ในช่วงเกิดพายุหรืออุณหภูมิที่ผิดปกติ ยกตัวอย่างเช่น บริเวณแหล่งน้ำมันและก๊าซธรรมชาติ ที่นี่ ชุดยึดที่ออกแบบมาให้ทนทานช่วยให้อุปกรณ์ตรวจสอบสามารถทำงานได้อย่างเหมาะสม แม้จะผ่านการถูกทิ้งไวภายใต้สภาพแวดล้อมเป็นเวลานานหลายเดือน ผลลัพธ์ที่ได้คือ ระบบมีอายุการใช้งานยาวนานขึ้น ไม่ต้องซ่อมแซมบ่อยๆ ซึ่งช่วยประหยัดค่าใช้จ่ายให้กับบริษัทที่ดำเนินงานภายใต้สภาพแวดล้อมที่ท้าทายนี้ในระยะยาว

การขนส่ง: การติดตั้งเครือข่ายรางที่ป้องกันการสั่นสะเทือน

สำหรับระบบรถไฟในทุกการขนส่งทั่วโลก ชิ้นส่วนยึดที่ออกแบบมาให้ทนต่อการสั่นสะเทือนพิเศษเหล่านี้มีความสำคัญอย่างมาก เมื่ออุปกรณ์ถูกติดตั้งไม่ถูกต้องบนรถไฟหรือราง ปัญหาต่างๆ ก็จะเกิดขึ้นบ่อยครั้ง และค่าใช้จ่ายในการซ่อมแซมก็จะเพิ่มขึ้นอย่างรวดเร็ว เช่น โครงการรถไฟสายหลักในชิคาโกเมื่อปีที่แล้ว ที่ได้เปลี่ยนชิ้นส่วนอุปกรณ์ยึดแบบเดิมเป็นตัวยึดใหม่ที่ช่วยดูดซับแรงสะเทือน ผลลัพธ์ที่ได้แตกต่างกันอย่างเห็นได้ชัด คือ ปัญหาขัดข้องลดลงในชั่วโมงเร่งด่วน และช่างเทคนิคใช้เวลาน้อยลงในการซ่อมแซมหน้าจอที่เคยหลุดออกบ่อยครั้ง ตัวยึดเหล่านี้สามารถทนต่อแรงสั่นสะเทือนอย่างต่อเนื่องจากความเคลื่อนไหวของรถไฟ ทำให้ผู้ควบคุมระบบไม่ต้องกังวลว่าหน้าจอแสดงผลจะทำงานผิดพลาดทุกครั้งที่มีทางโค้งในรางรถไฟ ปัจจุบันบริษัทรถไฟส่วนใหญ่จึงมองว่าตัวยึดแบบพิเศษเหล่านี้เป็นอุปกรณ์จำเป็น ไม่ใช่เพียงแค่ออปชันเสริม

การแพทย์: ชุดยึดที่สามารถทำให้ปราศจากเชื้อสำหรับห้องผ่าตัด

เมื่อพูดถึงโรงพยาบาลและห้องผ่าตัดโดยเฉพาะ ความต้องการของแขนยึดจอภาพที่สามารถฆ่าเชื้อได้นั้นมีความแตกต่างอย่างมากเมื่อเทียบกับอุปกรณ์สำนักงานทั่วไป การรักษาความสะอาดถือเป็นสิ่งสำคัญขั้นสุดท้ายที่นี่ เนื่องจากแม้แต่เชื้อแบคทีเรียในปริมาณน้อยที่สุดก็อาจก่อให้เกิดปัญหาร้ายแรงขึ้นได้ระหว่างการผ่าตัด แขนยึดเหล่านี้จำเป็นต้องสอดคล้องตามกฎระเบียบที่เข้มงวดมากมายที่องค์กรต่างๆ เช่น CDC และ FDA กำหนดเกี่ยวกับคุณสมบัติและการออกแบบอุปกรณ์ทางการแพทย์ ปัจจุบัน ระบบแขนยึดสมัยใหม่ส่วนใหญ่ผลิตจากวัสดุที่สามารถทนต่อการฆ่าเชื้อด้วยเครื่อง Autoclave ซ้ำๆ โดยไม่เสื่อมสภาพ ซึ่งช่วยให้รักษาความปราศจากเชื้อไว้ระหว่างการใช้งานแต่ละครั้ง ตัวยึดแบบพิเศษเหล่านี้ไม่เพียงแต่สอดคล้องตามมาตรการควบคุมการติดเชื้อเท่านั้น แต่ยังสามารถยึดจอภาพไว้ได้อย่างมั่นคง ตามตำแหน่งที่ศัลยแพทย์ต้องการมากที่สุดในระหว่างการผ่าตัด

คำถามที่พบบ่อย

วัสดุใดเหมาะสมที่สุดสำหรับราวจับหน้าจออุตสาหกรรม?

โลหะเกรดสูงอย่างเช่น เหล็กและอลูมิเนียม มักได้รับความนิยมเนื่องจากความทนทานและความสามารถในการใช้งานภายใต้สภาพแวดล้อมอุตสาหกรรมที่ยากลำบาก

ทำไมจึงสำคัญที่ต้องมีกระบวนการทดสอบสำหรับราวจับหน้าจอ?

โปรโตคอลการทดสอบช่วยให้มั่นใจถึงความทนทานและอายุการใช้งานของแขนยึดจอภาพอุตสาหกรรม โดยการจำลองสภาพแวดล้อมที่รุนแรง ซึ่งจะช่วยตรวจสอบอายุการใช้งานและประสิทธิภาพของผลิตภัณฑ์

แขนยึดจอภาพอุตสาหกรรมมีความแตกต่างจากผลิตภัณฑ์สำหรับผู้บริโภคอย่างไร

แขนยึดจอภาพอุตสาหกรรมโดยทั่วไปมีอายุการใช้งานยาวนานกว่า มีความทนทานสูงกว่า และต้องเปลี่ยนบ่อยน้อยกว่า ส่งผลให้ลดเวลาหยุดทำงานลง

ปัจจัยใดที่ควรคำนึงในการออกแบบแขนยึดสำหรับสถานที่เสี่ยงอันตราย

การออกแบบเฉพาะทาง วัสดุพิเศษ และการปฏิบัติตามมาตรฐานความปลอดภัย คือปัจจัยหลักในการออกแบบแขนยึดสำหรับสภาพแวดล้อมอันตราย

เทคโนโลยีการดูดซับแรงสั่นสะเทือนมีประโยชน์อย่างไรต่อโรงงานอุตสาหกรรม

เทคโนโลยีเหล่านี้ช่วยลดแรงสั่นสะเทือนที่อาจส่งผลต่อประสิทธิภาพและการใช้งานอุปกรณ์อิเล็กทรอนิกส์ในระยะยาว ลดความเสี่ยงของการเกิดข้อผิดพลาดและการหยุดทำงาน

ทำไมการกระจายน้ำหนึกจึงสำคัญสำหรับจอภาพขนาดใหญ่

การกระจายแรงน้ำหนักที่เหมาะสมจะช่วยลดความเสี่ยงจากการล้มเอียง ทำให้เกิดความปลอดภัยและการปฏิบัติตามมาตรฐานในพื้นที่อุตสาหกรรม

สารบัญ

- มาตรฐานความทนทานในตัวยึดจอภาพอุตสาหกรรม

- ความยืดหยุ่นในการออกแบบเพื่อรองรับสภาพแวดล้อมอุตสาหกรรมที่หลากหลาย

- ความต้านทานต่อการสั่นสะเทือนในเครื่องจักรขนาดใหญ่

- เหล็ก VS. อลูมิเนียม: การเปรียบเทียบสมรรถนะ

- โซลูชันแขนจับเฉพาะอุตสาหกรรม

-

คำถามที่พบบ่อย

- วัสดุใดเหมาะสมที่สุดสำหรับราวจับหน้าจออุตสาหกรรม?

- ทำไมจึงสำคัญที่ต้องมีกระบวนการทดสอบสำหรับราวจับหน้าจอ?

- แขนยึดจอภาพอุตสาหกรรมมีความแตกต่างจากผลิตภัณฑ์สำหรับผู้บริโภคอย่างไร

- ปัจจัยใดที่ควรคำนึงในการออกแบบแขนยึดสำหรับสถานที่เสี่ยงอันตราย

- เทคโนโลยีการดูดซับแรงสั่นสะเทือนมีประโยชน์อย่างไรต่อโรงงานอุตสาหกรรม

- ทำไมการกระจายน้ำหนึกจึงสำคัญสำหรับจอภาพขนาดใหญ่