The Rising Role of Monitor Arms in Automated Workflows

Driving Forces Behind Automation ErgonomicsÂ

Workplaces are seeing more automation these days, and along with that comes a real need for better ergonomics to keep workers productive while avoiding injuries. Organizations like OSHA have been pushing for ergonomic designs in offices for years now, pointing out how small changes can actually make big differences in both efficiency and accident rates. Monitor arms are becoming pretty popular in this space. These devices let people adjust their screens however they want, so different body types and preferences get accommodated without causing neck or eye strain. The flexibility makes sense when considering long hours at desks. Workers who can tweak their setup tend to stay healthier overall, which means fewer sick days and better output. This whole approach fits right into what some call automation ergonomics, where technology works alongside human needs instead of against them.

Evolution of Machine-Mounted Display Solutions

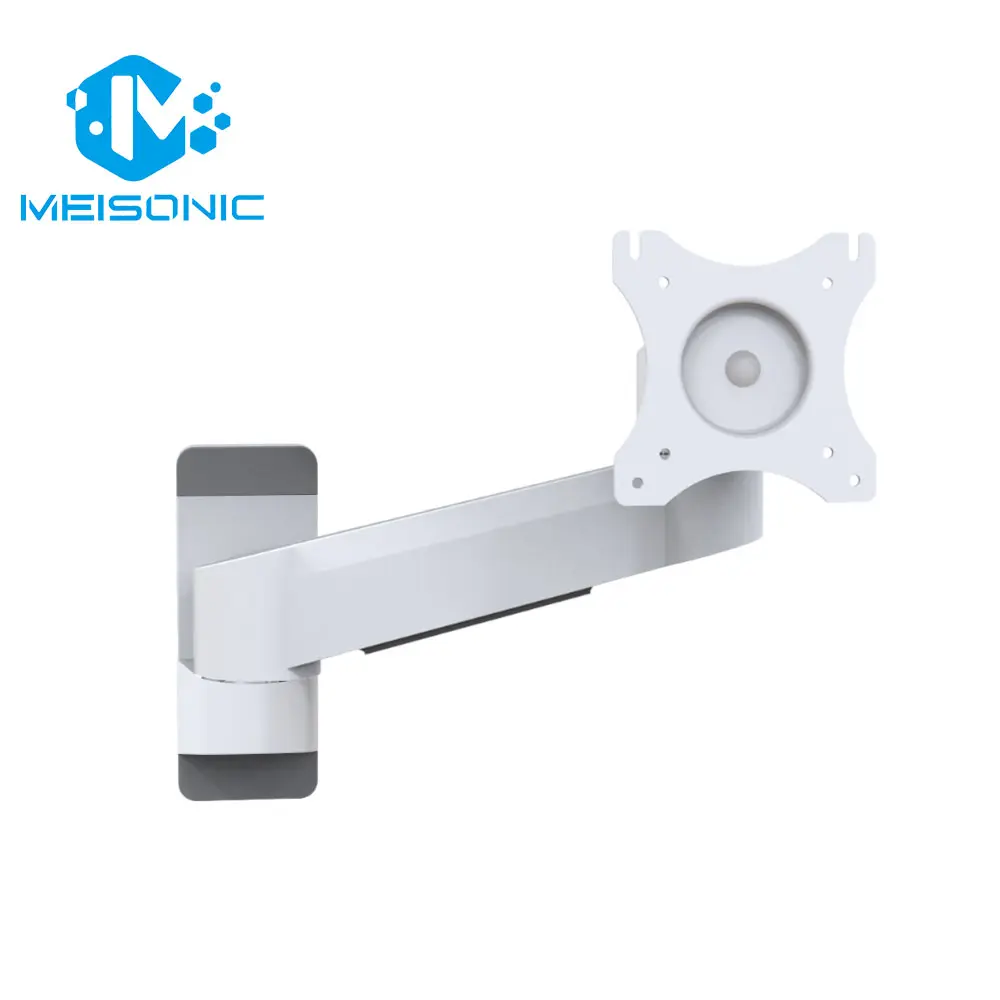

Monitor arms have come a long way since their days as basic fixed mounts. What started as simple hardware for holding screens has evolved into something much more versatile that meets today's ergonomic demands. Looking back at how these products developed shows us how tech progress changed both what they can do and how they look. The materials matter too. We've seen major upgrades in the stuff monitor arms are made from, which means they last longer and fit better in high-end office spaces without looking out of place. Smart tech is another game changer here. Many modern arms now connect wirelessly and adjust themselves automatically based on what workers need during different tasks. This makes a big difference in factories where displays need to move around machines constantly, streamlining operations while keeping everything visible exactly when it matters most.

Optimizing Human-Machine Interaction Through Ergonomic Positioning

Precision Viewing Angles for Error Reduction

Getting the right viewing angle matters a lot when it comes to cutting down eye strain and those pesky visibility errors that pop up all the time in automated workflows. When screens are positioned properly, workers actually see what they need to see without squinting or leaning forward, which cuts down on tired eyes and fewer slip-ups during long shifts. Some studies point to around a 30% drop in errors when people have their screens set up correctly, making automation run smoother overall. Monitor arms really shine here because they let folks tweak everything from height to tilt until it feels just right. These adjustable mounts aren't just fancy gadgets either they solve real problems for people who spend hours staring at computer screens day after day. The ability to customize means better comfort throughout the workday and keeps productivity steady even when things get busy.

Dynamic Adjustability Across Shifts

When several people take turns at the same workstation throughout the day, being able to adjust things on the fly makes all the difference for good ergonomics. Monitor arms that can be moved around let each person set up their screen just right based on how tall they are or what feels comfortable. This means no one has to struggle with awkward angles when switching from one shift to another. Different body types need different setups anyway, so having adjustable equipment really matters for keeping everyone happy and productive. The fact that these arms bend and twist to fit individual needs helps cut down on back pain and eye strain over time. Companies that invest in this kind of flexibility tend to see better results because workers stay more engaged and focused during their shifts, regardless of who happens to be sitting at the desk.

Maximizing Space Efficiency in Automated Machine Layouts

Vertical Space Utilization Strategies

Making better use of vertical space in workshop layouts really helps free up ground area, particularly when adding things like adjustable monitor arms to the mix. These arms let screens hang above workstations instead of sitting on top of them, giving back precious desk space that gets eaten up so fast. Some studies from manufacturing sectors show companies actually gain around 40% extra room just by switching to wall or ceiling mounted displays over standard desk setups. When workplaces start thinking vertically like this, it opens up the whole floor layout while making day to day operations smoother since there are fewer things getting in the way. The difference is noticeable too many shops report their work areas feel completely different after going through this change from chaotic messes to something much more organized where people can move around without bumping into equipment all the time.

Clutter-Free Maintenance Accessibility

A clean workspace really matters when it comes to staying efficient, particularly in places where automation does most of the work. Monitor arms are pretty important in this setup since they help keep everything organized and those pesky cables under control, which cuts down on the mess factor significantly. When installing these arms, many technicians find it helpful to attach some kind of cable management system right onto them so wires stay hidden instead of hanging around everywhere. Some research suggests that workplaces with less clutter see about a 30% boost in maintenance efficiency because workers don't waste time searching for tools or dealing with tangled wires. Operators who keep their areas neat generally finish maintenance jobs faster too, meaning machines spend less time offline and production stays on track without unnecessary delays.

Flexible Configuration Capabilities for Evolving Production Needs

Multi-Orientation Mounting Adaptations

Mounting systems that work in multiple orientations really matter when production needs change fast all the time. These adjustable monitor arms give factories exactly what they need to tweak their setup whenever demand shifts direction. Take automotive plants for example where workers can switch from one assembly line layout to another within minutes just by adjusting those monitors. Some companies report productivity jumps of 30% after implementing these flexible solutions. Quick adaptation means smoother operations day to day, but there's something else at stake too. Manufacturers who can pivot faster than competitors tend to win more contracts in today's manufacturing landscape where customer demands evolve constantly.

Scalable Arm Systems for Line Reconfigurations

When production lines need to change, scalable arm systems become really important for keeping up with those changes. Manufacturers love these systems because they let them tweak and rearrange their setup without having to throw away everything and start fresh, which saves money in the long run. Factories around the world are moving toward modular designs these days. We've seen this happen at several plants where workers reported being able to switch between different product runs much faster than before. For companies thinking ahead, going with scalable solutions means staying flexible when market needs shift. This kind of forward planning helps streamline day to day operations while also giving businesses an edge against competitors who might be stuck with outdated equipment.

Enhancing Workplace Safety with Engineered Monitor Arm Solutions

Hazard Zone Visibility Enhancements

Monitor arms make a big difference for seeing clearly in dangerous work areas, which helps keep people safe on the job. When workers can adjust their screens to just the right angle, they get better views around machinery where blind spots used to be problems. The numbers back this up too. OSHA reports suggest workplaces see about a quarter fewer incidents when folks actually have good sightlines. These days manufacturers are working hard to design arms that give great visibility without messing up proper ergonomics. Machines stay easy to operate while employees don't strain their necks or backs trying to see what's going on. Getting visibility right matters beyond just preventing accidents it actually makes daily operations run much more smoothly across different industries.

Anti-Fatigue Design for Extended Monitoring

Monitor arms designed to combat fatigue play a big role in keeping workers comfortable when they spend long hours at their desks. Features like height adjustment and angle flexibility really cut down on neck and eye strain, something that translates into fewer sick days and better performance overall. Research indicates that making simple ergonomic changes can boost worker output by around 15% after some time. Beyond just getting more done, these designs actually make a difference in how employees feel day to day. This matters a lot in settings like manufacturing plants or control rooms where people need to keep watch for hours on end. When physical discomfort isn't constantly nagging at them, staff members tend to stay healthier and more invested in their jobs. Companies that invest in these kinds of solutions often find themselves with happier teams who stick around longer because their workspace actually supports good health rather than undermining it.

FAQ

What are monitor arms and how do they contribute to workplace ergonomics?

Monitor arms are adjustable brackets that hold computer monitors. They allow users to position screens in ways that reduce strain on the neck and eyes, contributing to ergonomic improvements that enhance productivity and decrease the risk of injuries.

How can monitor arms help in maximizing space efficiency?

Monitor arms can be mounted off desks, freeing up valuable desktop space. This vertical arrangement optimizes space utilization and contributes to a cleaner, more efficient working environment.

Are adjustable monitor arms beneficial for multi-shift operations?

Yes, adjustable monitor arms provide dynamic repositioning capabilities that accommodate various user heights and preferences, essential for comfort across multiple shifts, enhancing employee satisfaction and productivity.

Can monitor arms affect productivity positively?

Monitor arms allow for precision viewing angles that reduce errors and strain. By allowing customization to individual needs, they create a comfortable workplace that can lead to improved productivity.

How do monitor arms contribute to workplace safety?

Monitor arms enhance visibility in hazard zones by optimizing screen angles, which can reduce workplace incidents. Their ergonomic design also ensures correct posture, preventing strain during extended monitor use.

Table of Contents

- The Rising Role of Monitor Arms in Automated Workflows

- Optimizing Human-Machine Interaction Through Ergonomic Positioning

- Maximizing Space Efficiency in Automated Machine Layouts

- Flexible Configuration Capabilities for Evolving Production Needs

- Enhancing Workplace Safety with Engineered Monitor Arm Solutions

- FAQ