Աճող դերը Դիսպլայ համակարգեր ավտոմատացված գործարաններում

Ավտոմատացման Էրգոնոմիկայի Ետևում Գործող Շարժիչ Ուժեր

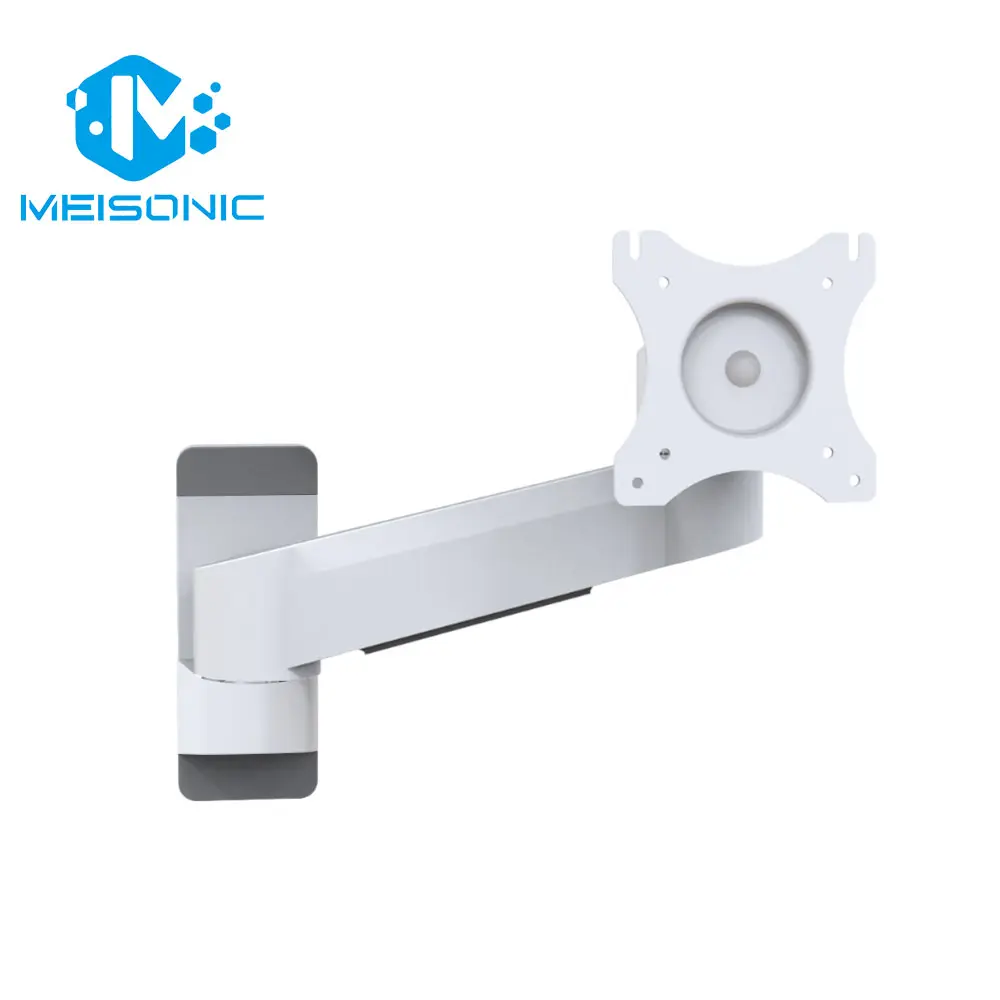

Վերջին տարիներին աշխատատեղերում ավելի շատ ավտոմատացում է տեղի ունենում, և դրա հետ մեկտեղ առաջանում է ավելի լավ էրգոնոմիկայի իրական կարիք, որպեսզի աշխատանքային նախաձեռնությունները պահպանվեն արտադրողական, իսկ վնասվածքները կանխվեն: Օրինակ, OSHA-ն տարիներ առաջ սկսել է քարոզել աշխատանքային տարածքներում էրգոնոմիկ դիզայների կիրառումը, ընդգծելով, թե ինչպես կարող են փոքր փոփոխություններ մեծ ազդեցություն ունենալ արդյունավետության և վթարների ցուցանիշների վրա: Հետևաբար, համակարգչային մոնիտորների համար ամրակները հաճախադեպ կիրառվում են այս ոլորտում: Այդ սարքերը թույլ են տալիս մարդկանց կարգավորել իրենց էկրանները ըստ ցանկության, այնպես որ տարբեր մարմնակազմերն ու նախընտրությունները հաշվի են առնվում առանց պարանոցի և աչքերի լարվածության: Այդ ճկունությունը տրամաբանական է, հաշվի առնելով աշխատանքի երկար ժամերը գրասեղանի մոտ: Այն աշխատողները, ովքեր կարողանում են կարգավորել իրենց աշխատանքային տեղը, ավելի առողջ են մնում, ինչը նշանակում է ավելի քիչ հիվանդացման օրեր և ավելի լավ արտադրողականություն: Այս մոտեցումը համապատասխանում է այն հասկացությանը, որը որոշ մասնագետներ անվանում են ավտոմատացման էրգոնոմիկա, որտեղ տեխնոլոգիան մարդկային կարիքների հետ միասին է աշխատում, ոչ թե դեմ իրար:

Մեքանիզմների վրա դիսպլեյի լուծումների էvoluciónացիա

Մոնիտորի բազկերը իրենց սկզբնական շրջանից հետո, երբ դրանք պարզապես ամրակապ սարքեր էին, մեծ ճանապարհ են անցել: Այն, ինչ սկսվել է որպես պարզ սարք՝ էկրաններ տեղադրելու համար, վերափոխվել է ավելի բազմակողմանի սարքավորումների, որոնք համապատասխանում են այսօրվա էրգոնոմիկ պահանջներին: Նայելով այդ բազկերի զարգացման պատմությանը, մենք տեսնում ենք, թե ինչպես է տեխնոլոգիական առաջընթացը փոխել ինչպես դրանց հնարավորությունները, այնպես էլ դրսի տեսքը: արտադրանքներ զգալի է նաև նյութերի դերը: Մենք տեսնում ենք կարևոր բարելավումներ մոնիտորի բազկերի համար օգտագործվող նյութերում, ինչը նշանակում է, որ դրանք ավելի երկար են ծառայում և ավելի լավ են հարմարվում բարձր դասի գրասենյակային տարածքներում՝ առանց տեղից դուրս տեսք ունենալու: Հերթական խաղափոխությունը տեղի է ունենում հենց ինտելեկտուալ տեխնոլոգիաների շնորհիվ: Շատ նորատիպ բազկեր այժմ ապահովում են անմիջական կապ և ինքնաբերաբար կարգավորվում են աշխատանքի տարբեր փուլերում աշխատողների կարիքներին համապատասխան: Դա մեծ տարբերություն է անում արդյունաբերական ձեռնարկություններում, որտեղ էկրանները պետք է մեքենաների շուրջ շարժվեն՝ աշխատանքը հեշտացնելու և ապահովելու համար, որ ամեն ինչ տեսանելի լինի ճիշտ ժամանակին:

Երկարաչափական դիրքերի միջոցով մարդ-մեքենային համակարգերի օպտիմալացում

Դիտարկման անկյունների ճշգրիտությունը սխալերի նվազեցման համար

Ճիշտ տեսանկյուն ստանալը շատ կարևոր է, երբ խոսքը գնում է աչքերի լարվածությունը և ավտոմատացված աշխատանքային հոսքերում հաճախադեպ առաջացող տեսանելիության սխալները նվազեցնելու մասին: Երբ էկրանները ճիշտ են տեղադրված, աշխատակիցները իրոք տեսնում են այն, ինչ պետք է, առանց աչքերը սեղմելու կամ առաջ թեքվելու, ինչը նվազեցնում է աչքերի հոգնածությունը և երկար աշխատանքային տեղերում սխալների քանակը: Որոշ հետազոտություններ ցույց են տվել, որ ճիշտ էկրանի տեղադրման դեպքում սխալները նվազում են մոտ 30%-ով, ինչը ավտոմատացիան ավելի հարթ դարձնում է ընդհանրապես: Այստեղ հատկապես աչքի են ընկնում մոնիտորի բազկերը, քանի որ դրանք թույլ են տալիս մարդկանց ճշգրտել բարձրությունից մինչև թեքությունը ամեն ինչ, մինչև ամեն ինչ ճիշտ զգալ: Այս կարգավորվող պարկետները ոչ միայն ճաշակով սարքեր են, այլ լուծում են իրական խնդիրներ այն մարդկանց համար, ովքեր ժամեր շարունակ աշխատում են համակարգիչների առջև: Կարգավորման հնարավորությունը նշանակում է ավելի լավ հարմարավետություն ամբողջ աշխատանքային օրվա ընթացքում և ապահովում է արտադրողականությունը, նույնիսկ երբ աշխատանքը դժվարանում է:

Դինամիկ կարգավորելիություն շիֆտերի ընթացքում

Երբ մի քանի մարդ օրվա ընթացքում միևնույն աշխատանքային տեղում հերթականությամբ աշխատում են, հնարավորություն ունենալը ամենօրյա ճկուն կերպով ամեն ինչ կարգավորելու համար լավ էրգոնոմիկայի համար մեծ նշանակություն ունի: Այն հնարավորությունը, որ էկրանի բազկերը կարող են տեղաշարժվել, թույլ է տալիս յուրաքանչյուր մարդու համար էկրանը ճիշտ կերպով տեղադրել համապատասխան հասակին կամ հարմարավետության զգացումներին համապատասխան: Սա նշանակում է, որ մարդիկ այլևս չեն ստիպված լինում անհարմար անկյունների հետ կռվել մի թիմից մյուսին անցնելու դեպքում: Այն ճիշտ է, որ տարբեր կառուցվածքների մարդկանց համար տարբեր կարգավորումներ են անհրաժեշտ, այդ իսկ պատճառով ճկուն սարքավորումների ներդրումը կարևոր է բոլորի բարեկեցության և արտադրողականության համար: Այն փաստը, որ այդ բազկերը ճկվում և պտտվում են անհատական կարիքներին համապատասխան, օգնում է նվազեցնել ետքի ցավերն ու աչքերի լարվածությունը ժամանակի ընթացքում: Կազմակերպությունները, որոնք ներդնում են այդպիսի ճկունություն, ավելի լավ արդյունքներ են ստանում, քանի որ աշխատակիցները ավելի ներգրավված ու կենտրոնացած են մնում իրենց աշխատանքի ընթացքում, անկախ նրանից, թե ով է այդ պահին աշխատանքային սեղանի մոտ նստած:

Տարածքի արդյունավետության առավելացումը ավտոմատացված մեքենաների դասավորման մեջ

Վերթիկական տարածքի օգտագործման կարգեր

Ավելի լավ օգտագործելով վերտիկալ տարածքը արհեստանոցների դասավորումներում՝ իրականում հնարավոր է ազատել հատակի տարածքները, մասնավորապես՝ ավելացնելով հարմարեցվող հեռուստացույցների բազուկների նման իրեր: Այդ բազուկները թույլ են տալիս էկրանները կախված լինեն աշխատանքային սեղանների վրայից, ոչ թե դրված լինեն վրան: Սա հնարավորություն է տալիս վերադարձնել այն թանկարժեք սեղանի տարածքը, որը շատ արագ է զբաղվում: Արտադրող ոլորտներից որոշ հետազոտություններ ցույց են տվել, որ ընկերությունները իրականում ստանում են մոտ 40% ավելի շատ տեղ պարզապես անցնելով ստանդարտ սեղանի կարգավորումներից մինչև պատին կամ առաստաղին մի փոխարկված ցուցադրումներ: Երբ աշխատանքային տարածքները սկսում են մտածել այսպիսով՝ վերտիկալ, ապա ամբողջ հնարավոր է ազատել հատակի տարածքները, իսկ ամենօրյա գործողությունները դառնում են ավելի հեշտ, քանի որ ավելի քիչ բան է խոչընդոտում: Տարբերությունը նկատելի է. շատ խանութներ հայտնում են, որ իրենց աշխատանքային տարածքները զգում են ամբողջովին այլ կերպ՝ անցնելով այս փոփոխությունից հետո՝ ամայի խառնաշփոթից մինչև ավելի կարգավորված տարածք, որտեղ մարդիկ կարող են շարժվել առանց մշտապես բաump հարվածելու սարքերին:

Անկարգ աշխատանքային տարածքի հասանելիություն

Աշխատանքային տարածքի մաքրությունը շատ կարևոր է, երբ խոսքը արդյունավետության մասին է, հատկապես այն տեղերում, որտեղ ավտոմատացումն է կատարում մեծամասնակի աշխատանքը: Այս կարգավորման մեջ հսկիչի բազկերը շատ կարևոր են, քանի որ նրանք օգնում են ամեն ինչ կարգի բերել և ապահովել անհանգստացնող սարքերի կարգավորումը, ինչը զգալիորեն նվազեցնում է անկարգությունը: Բազկերը տեղադրելիս շատ տեխնիկաներ օգտակար են գտնում դրանց վրա մի տեսակի սարքերի կառավարման համակարգ ամրացնել, որպեսզի հաղորդալարերը թաքնված մնան և չեն կախվի ամենուր: Որոշ հետազոտություններ ցույց են տվել, որ աշխատանքային տեղերում, որտեղ ավելի քիչ անկարգություն կա, սպասարկման արդյունավետությունը մոտ 30% ավելի բարձր է, քանի որ աշխատողները ժամանակ չեն կորցնում գործիքներ փնտրելու կամ բարդ հաղորդալարերի հետ կեղտոտ աշխատանքի համար: Այն օպերատորները, ովքեր պահպանում են իրենց տարածքները մաքուր, սպասարկման աշխատանքներն էլ ավելի արագ են ավարտում, ինչը նշանակում է, որ մեքենաները ավելի քիչ ժամանակ են կանգնած և արտադրությունը շարունակվում է առանց ավելորդ ուշացումների:

Կարգավորման հնարավորություններ փոխվող արտադրության պահանջներին

Բազմաուղղության մուտքագրման այցեր

Արտադրության արագ փոփոխվող կարիքների դեպքում բազմակողմանի կիրառություն ունեցող ամրացման համակարգերն իսկապես կարևոր են: Այս կարգավորվող մոնիտորների բազուկները գործարաններին տրամադրում են հենց այն հնարավորությունը, որպեսզի կարողանան ճշգրտել իրենց կազմավորումը՝ կախված պահանջարկի փոփոխություններից: Վերցրեք օրինակի համար ավտոմոբիլաշինության գործարանները, որտեղ աշխատողները կարող են մի արտադրական գիծ ամբողջովին փոխել մեկ այլ կազմավորման միայն մոնիտորները կարգավորելով: Որոշ ընկերություններ տեղեկացնում են, որ արդյունավետությունը աճել է 30%-ով այս ճկուն լուծումները ներդնելուց հետո: Արագ հարմարվելը ամենօրյա ավելի հեշտացված գործողություններ է նշանակում, սակայն այստեղ մի այլ հարց էլ կա: Արտադրողները, ովքեր կարողանում են ավելի արագ փոխվել, քան մրցակիցները, հնարավորություն ունեն ավելի շատ պայմանագրեր ստանալ այն արդյունաբերական միջավայրում, որտեղ հաճախորդների պահանջները անընդհատ փոփոխվում են:

Դիսպլեյ Ձեռնարկերի Սկալաբել Համակարգեր Ժամանակավոր Կարգավորումների Համար

Երբ արտադրական գծերը փոփոխությունների են ենթարկվում, մասշտաբային բազկերի համակարգերը շատ կարևոր են դառնում այդ փոփոխություններին համապատասխանելու համար։ Արտադրողները սիրում են այդ համակարգերը, քանի որ նրանք հնարավորություն են տալիս նրանց ճկուն կերպով փոփոխել և վերադասավորել իրենց կազմաձևը՝ առանց ամեն ինչ նորից սկսելու, ինչը երկար ժամանակ անց փոխհատուցում է ծախսերը։ Այսօր ամբողջ աշխարհում գործարանները ձգտում են դեպի մոդուլային նախագծումներ։ Մենք այդ պատկերը տեսել ենք մի քանի գործարաններում, որտեղ աշխատողները նշել են, որ կարողանում են ավելի արագ անցնել տարբեր արտադրական շարքերի միջև, քան ավելի վաղ։ Կազմակերպությունների համար, որոնք մտածում են ապագայի մասին, մասշտաբային լուծումներ ընդունելը նշանակում է մնալ ճկուն, երբ շուկայի կարիքները փոխվում են։ Այդպիսի նախօրոք պլանավորումը օգնում է օպտիմալացնել ամենօրյա գործողությունները՝ միաժամանակ առավելություն տրամադրելով մրցակիցների նկատմամբ, ովքեր կարող է հնացած սարքավորումների հետ մնալ ամրանալ

Ենթադրական անդամների համակարգերի միջոցով աշխատանքային տանիքի ան전ության ավելացում

Ստորագրության տարածքի տեսակավորության ավելացում

Մոնիտորի բազկերը մեծ նշանակություն ունեն վտանգավոր աշխատանքային տարածքներում հստակ տեսանելիություն ապահովելու համար, ինչը օգնում է պահպանել անվտանգությունը աշխատանքի ընթացքում: Երբ աշխատողները կարողանում են էկրանները ճիշտ անկյունով կարգավորել, մեքենաների շուրջ տեսանելիությունը բարելավվում է, որտեղ ավելի վաղ կույր գոտիներ կային: Թվերը ևս այս մտքի աջակցությունն են տրամադրում: Ըստ OSHA զեկույցների, աշխատավայրերում վթարների քանակը մոտ մեկ քառորդով նվազում է, երբ աշխատողները իրոք լավ տեսանելիություն ունեն: Այսօրվա մատակարարները ջանքեր են գործադրում այնպիսի բազկեր ստեղծելու համար, որոնք ապահովում են լավ տեսանելիություն առանց էրգոնոմիկայի խախտման: Մեքենաները հեշտ է կառավարել, իսկ աշխատողները չեն մաշվում պարանոցով և ետքով փորձելով տեսնել, թե ինչ է տեղի ունենում: Տեսանելիության ճիշտ կարգավորումը կարևոր է ոչ միայն վթարների կանխման համար, այլ նաև ամենօրյա գործընթացների ավելի հարթ կատարման համար տարբեր արդյունաբերություններում:

Հանգույցի դիմանում համարակալ նախագծման համար

Մոնիտորի բազկերը, որոնք նախագծված են հոգնածությունը մարելու համար, մեծ դեր են խաղում աշխատանքային սեղանի մոտ երկար ժամեր անցկացնող աշխատողների հարմարավետությունը պահպանելու գործում: Բարձրության և անկյան ճկուն կարգավորումը իսկապես նվազեցնում է պարանոցի և աչքերի լարվածությունը, ինչը թարգմանվում է ավելի քիչ հիվանդացության և ընդհանուր առմամբ ավելի լավ արդյունքների: Գիտազնանդություններ ցույց են տվել, որ պարզ էրգոնոմիկ փոփոխություններ կատարելը կարող է աշխատողների արտադրողականությունը մոտ 15% բարձրացնել որոշակի ժամանակ անց: Ավելի շատ աշխատանք կատարելուց բացի, այս նախագծումները իրոք ազդում են աշխատակիցների ամենօրյա զգացումների վրա: Սա հատկապես կարևոր է այնպիսի միջավայրերում, ինչպես օրինակ արտադրական գործարանները կամ կառավարման սրահները, որտեղ մարդիկ պետք է մի քանի ժամ շարունակ հսկողություն իրականացնեն: Երբ ֆիզիկական անհարմարությունները մշտապես չեն ազդում նրանց վրա, աշխատանքային կազմը ավելի առողջ և ներգրավված է մնում իրենց աշխատանքում: Կազմակերպությունները, որոնք ներդնում են այսպիսի լուծումների մեջ, հաճախ ավելի բավարարված թիմեր են ստանում, քանի որ աշխատանքային տարածքը աջակցում է լավ առողջությանը, այլ ոչ թե դեմ է առնում դրան:

Հաճախ տրամադրվող հարցեր

Ինչ են մոնիտորների արձակող համակարգերը և ինչպես նրանք աջակցում են աշխատանքային երգոնոմիկային պայմանները?

Դիսպլեյի արկները համարվում են կարգավոր փակագծեր, որոնք պահում են կոմպյուտերային դիսպլեյներ: Նրանք թողնում են օգտագործողներին դիսպլեյները դրանցն այնպես դիրքավորել, որ նվազեցնեն բոլոր տարածքների և աչքերի արձանագրությունը՝ առաջարկելով էրգոնոմիկ լուծումներ, որոնք ավելացնում են արդյունավետությունը և նվազում են վարույթների անտառության ռիսկը:

Ինչպես կարող են դիսպլեյի արկերը օգնել տարածքի արդյունավետությունը առավելացնել?

Դիսպլեյի արկերը կարող են մուտքագրվել աշխատանքային սեղաններից դուրս, ազատացնելով արժանի սեղանի տարածք: Այս ուղիղ դասավորությունը օպտիմալացնում է տարածքի օգտագործումը և ներդրում է ավելի կարգավոր և արդյունավետ աշխատանքային միջավայր:

Ենթադրվում է՞ դիսպլեյի արկերի կարգավորությունը օգտագործվելու է մի քանի սhift-ի համար?:

Այո, կարգավոր դիսպլեյի արկերը բարձրացնում են դինամիկ դիրքավորման հնարավորությունները, որոնք համապատասխանում են տարբեր օգտագործողների բարձրության և նախագծումներին, որը անհրաժեշտ է հանգույցի համար մի քանի սhift-ի միջև, ավելացնում են աշխատակիցների բավարարությունը և արդյունավետությունը:

Կարող են դիսպլեյի համակարգերը դրամաτιկ ձևով ավելացնել աշխատանքային արդյունքները:

Դիսպլեյի համակարգերը թույլ են տալիս ճշգրիտ դիտանկյուններ, որոնք նվազուցնում են սխալները և բարդությունը: Անհրաժեշտ կարգավորումների թույլատրելով, դրանք ստեղծում են հարմար աշխատանքային միջավայր, որը կարող է բարելավել աշխատանքային արդյունքները:

Ինչպես են դիսպլեյի համակարգերը նպաստում աշխատանքային աمانյանը:

Դիսպլեյի համակարգերը բարձրացնում են տեսական հասկացությունը gevorgneran տարածություններում՝ օպտիմալ դիսպլեյի անկյուններով, ինչը կարող է նվազեցնել աշխատանքային առաջացուցիչները: Նրանց երկարակային դիսպլեյի օգտագործման ժամանակ նաև ապահովում են ճիշտ դիրք, որը պարունակում է բարդությունները:

Բովանդակության աղյուսակ

- Աճող դերը Դիսպլայ համակարգեր ավտոմատացված գործարաններում

- Երկարաչափական դիրքերի միջոցով մարդ-մեքենային համակարգերի օպտիմալացում

- Տարածքի արդյունավետության առավելացումը ավտոմատացված մեքենաների դասավորման մեջ

- Կարգավորման հնարավորություններ փոխվող արտադրության պահանջներին

- Ենթադրական անդամների համակարգերի միջոցով աշխատանքային տանիքի ան전ության ավելացում

- Հաճախ տրամադրվող հարցեր