Material Importa: Cómo Brazo de Monitor Industrial Composición Impacta el Rendimiento

Relación de Resistencia-Peso en Aplicaciones Pesadas

Al elegir materiales para brazos de monitor de uso intensivo, la relación resistencia-peso es muy importante. Básicamente, esto significa que el brazo debe soportar un peso considerable sin ser demasiado pesado, lo que mejora el funcionamiento general y ahorra materiales. Por ejemplo, en la actualidad el aluminio y la fibra de carbono son muy populares porque ofrecen gran resistencia sin añadir mucho volumen. Ideales para lugares donde se necesita algo fuerte pero no incómodo. El acero es otra opción, aunque es más pesado en relación con la carga que puede soportar. Aún así, muchos fabricantes optan por acero en ciertas situaciones donde la durabilidad a largo plazo es más importante que el peso. Después de todo, nadie quiere que su brazo para monitor se colapse tras años de uso diario solo porque alguien eligió el material más liviano posible. La elección correcta siempre depende de encontrar el punto óptimo entre el peso que debe soportar y el peso real del brazo, especialmente importante en fábricas y talleres donde las normas de seguridad son estrictas.

Resistencia a la Corrosión para Condiciones Operativas Severas

Los brazos de monitor instalados en entornos industriales exigentes enfrentan amenazas serias de corrosión que pueden reducir considerablemente su rendimiento y durabilidad. Factores como altos niveles de humedad, exposición a diversos productos químicos y aire salino actúan conjuntamente para degradar los materiales a un ritmo alarmante. Por esta razón, la resistencia a la corrosión debe formar parte del proceso de planificación de cualquier equipo serio. La construcción en acero inoxidable y el aluminio con un recubrimiento en polvo de alta calidad destacan como materiales capaces de combatir estas fuerzas destructivas. Estudios indican que los brazos de monitor que carecen de defensas adecuadas contra la corrosión suelen fallar aproximadamente un tercio más pronto de lo esperado cuando se ubican cerca de zonas de procesamiento químico o en zonas costeras donde la sal siempre está presente en el aire. Cuando las empresas eligen materiales adecuados con resistencia a la corrosión, obtienen equipos más duraderos que continúan funcionando de manera confiable incluso bajo ataques de condiciones ambientales adversas. Esto se traduce en menos fallos inesperados y ahorros en costos de reparación a lo largo del tiempo.

Amortiguación de Vibraciones e Integridad Estructural

El control adecuado de las vibraciones es muy importante para mantener los brazos de monitor industriales intactos con el tiempo. Cuando estos brazos se instalan en plantas de fabricación o dentro de talleres de reparación automotriz donde las máquinas constantemente generan movimientos, entran en juego materiales especiales. Los polímeros viscoelásticos funcionan bien en este contexto, junto con polietileno de alta densidad que absorbe esas pequeñas vibraciones molestas antes de que causen problemas. Esto significa prácticamente equipos más duraderos, ya que la constante vibración no los desgasta tan rápidamente. Además, las pantallas permanecen alineadas correctamente sin desplazarse accidentalmente. Algunas investigaciones han mostrado que una buena gestión de vibraciones puede duplicar en algunos casos la vida útil del equipo, quizás incluso más del 40% en ciertas situaciones. Para los trabajadores que necesitan que sus pantallas estén estables mientras realizan tareas importantes, contar con un amortiguamiento confiable marca la diferencia entre operaciones fluidas y tiempos muertos frustrantes causados por monitores inestables.

Por qué el Aleación de Aluminio Domina en el Diseño de Brazos de Monitores Industriales

Durabilidad de Grado Aeroespacial en un Formato Compacto

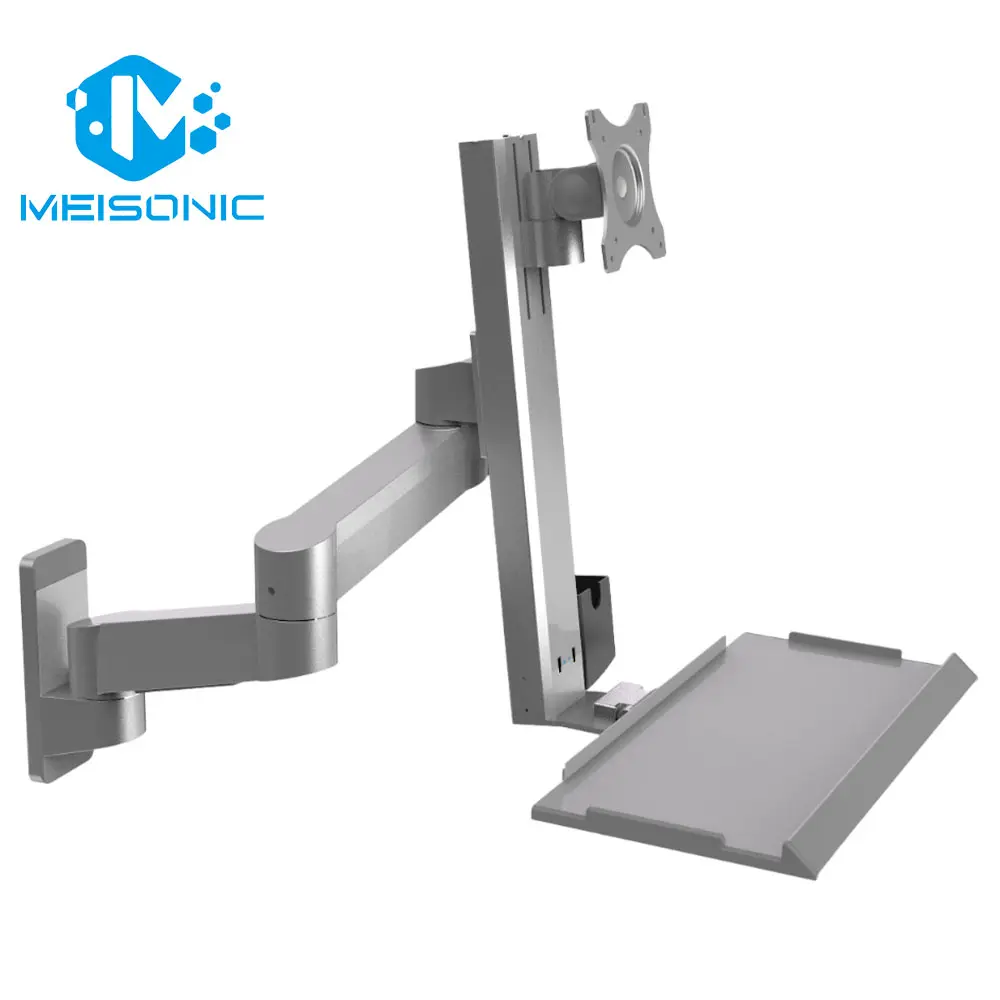

Las aleaciones de aluminio se han convertido casi en estándar en los brazos para monitores industriales porque resisten muy bien, casi como lo que se utiliza en aviones. Lo que las hace especiales es esta increíble combinación de ser suficientemente fuertes para sostener monitores pesados, pero aún así lo bastante ligeras para no añadir peso innecesario. Esto es muy importante cuando los trabajadores necesitan ajustar las pantallas durante el día sin forzar su espalda. La forma en que estos brazos ocupan espacio en los escritorios es otro punto a favor. Se adaptan perfectamente en espacios reducidos pero permanecen estables incluso cuando alguien tiene tres monitores funcionando al mismo tiempo o necesita mover equipos con frecuencia. La mayoría de las empresas que venden este tipo de equipos suelen destacar a sus clientes lo duradero que es realmente el aluminio, especialmente porque sigue funcionando de manera confiable incluso después de años de uso constante en fábricas donde el polvo y las vibraciones forman parte de la vida diaria.

Resistencia a la oxidación sin recubrimientos adicionales

Las aleaciones de aluminio tienen algo que las destaca realmente frente a otras materiales: su resistencia natural a la oxidación les da una gran ventaja en todo tipo de entornos industriales. La mayoría de los demás materiales necesitan recubrimientos especiales solo para evitar la corrosión, pero el aluminio combate la oxidación por sí solo, lo que significa menos trabajo de mantenimiento y una vida útil más larga para cosas como brazos de monitor. Por eso muchas personas en los sectores de fabricación y construcción se inclinan por el aluminio puro cuando evalúan opciones de materiales. El metal simplemente no requiere tanto esfuerzo en mantenimiento, y las operaciones funcionan de manera más fluida en general, ya que no hay una necesidad constante de retoques o aplicación de capas adicionales de protección.

Conductividad térmica para entornos sensibles al calor

Las aleaciones de aluminio funcionan realmente bien cuando es fundamental mantener las cosas frías, ya que conducen el calor de manera muy eficaz. Su capacidad para disipar el calor hace que sean opciones excelentes para lugares en los que gestionar la temperatura es superimportante, piense en dispositivos electrónicos o equipos de fábrica. Cuando se instalan, por ejemplo, en brazos de monitor, estas aleaciones mantienen la temperatura estable con el tiempo. Esto ayuda a prolongar la vida útil del equipo, ya que evita que los componentes se sobrecalienten y se dañen. Pruebas reales demuestran lo mucho mejor que el aluminio gestiona el calor en comparación con otros materiales. Por eso vemos a tantos fabricantes recurriendo a soluciones de aluminio siempre que tienen que lidiar con productos sensibilidad al exceso de calor.

Confrontación de Materiales: Aleación de Aluminio vs Acero vs Plásticos de Ingeniería

Comparación de Capacidad de Carga: Esfuerzos Estáticos vs Dinámicos

Al evaluar los brazos para monitores industriales, es fundamental determinar cuánto peso pueden soportar bajo esfuerzos normales y repentinos al momento de elegir los materiales a utilizar. Las aleaciones de aluminio destacan porque resisten bien la presión manteniendo un peso ligero que facilita su movimiento, lo que las hace ideales para situaciones en las que el brazo deba ajustarse con frecuencia. El acero es otra alternativa que resiste muy bien las cargas constantes, por lo que resulta más adecuado para instalaciones fijas donde el peso adicional no sea un inconveniente. Los plásticos técnicos también son ligeros, pero suelen deteriorarse más rápido bajo movimientos o vibraciones constantes. Sin embargo, tienen su aplicación, especialmente en ambientes donde la humedad o productos químicos puedan dañar los componentes metálicos con el tiempo. Una buena forma de comparar el desempeño de todos estos materiales sería mediante una tabla sencilla que muestre su comportamiento bajo distintas condiciones de esfuerzo. Conocer estos aspectos ayuda a las empresas a seleccionar el material más adecuado según las exigencias específicas a las que su equipo estará expuesto diariamente.

Requisitos de mantenimiento a través de tipos de materiales

Saber qué tipo de mantenimiento requiere cada material, como las aleaciones de aluminio, el acero y los plásticos técnicos, puede ahorrar dinero a las empresas y mantener las operaciones funcionando sin contratiempos. El aluminio destaca porque requiere poco mantenimiento gracias a su resistencia natural a la corrosión. Esto significa que las piezas fabricadas en aluminio duran más sin necesidad de recubrimientos o tratamientos adicionales. El acero, por otro lado, es fuerte pero necesita atención constante. Se requiere mantenimiento regular para evitar que se forme óxido y cause daños que lleven a reparaciones costosas y retrasos en la producción. Los plásticos técnicos se encuentran en una posición intermedia. No se corroen como los metales, por lo que su mantenimiento es mínimo en general. Sin embargo, en aplicaciones donde las cargas son elevadas, las inspecciones periódicas son importantes para detectar signos de desgaste antes de que surjan problemas. La mayoría de los profesionales del sector suelen inclinarse por el aluminio al hablar de materiales que reducen las complicaciones de mantenimiento, especialmente en industrias como la aeroespacial o la fabricación automotriz, donde la fiabilidad del equipo impacta directamente en la productividad.

Costo Total de Propiedad a lo Largo del Ciclo de Vida del Producto

Al analizar el costo total de propiedad (TCO) de brazos para monitores industriales, debemos considerar los costos iniciales, la cantidad de mantenimiento que requieren y su durabilidad antes de fallar. Las aleaciones de aluminio suelen ofrecer bastante buena relación calidad-precio en este aspecto, ya que resisten bien el desgaste y no necesitan reparaciones o reemplazos constantes. Las opciones de acero tienen un costo inicial más elevado y además requieren inspecciones periódicas de mantenimiento que, con los años, incrementan su costo total. Los componentes plásticos pueden parecer más económicos a simple vista, pero rara vez soportan las condiciones duras de una fábrica sin agrietarse o deformarse tras unos pocos meses. Los gerentes de fábrica que han calculado los costos reales del equipo han encontrado que el aluminio siempre resulta más ventajoso en la mayoría de las instalaciones, especialmente en aquellas que operan las 24 horas del día, donde el tiempo de inactividad genera costos y la calidad del producto depende de sistemas de monitoreo estables durante todo el turno.

Conclusión: Aleación de Aluminio como Referencia para Brazos de Monitores Industriales

Equilibrando Rendimiento y Práctica

Cuando se trata de brazos para monitores industriales, la aleación de aluminio realmente encuentra el punto óptimo entre el rendimiento y la practicidad de uso. Este material es ligero pero extremadamente resistente, razón por la cual muchos fabricantes vuelven una y otra vez a utilizarlo. Los profesionales suelen destacar lo versátiles que pueden ser estos brazos manteniendo su resistencia día a día sin fallar. El aluminio maneja tanto partes móviles como posiciones fijas sin problema, algo que tiene mucho sentido considerando las múltiples formas en que la gente organiza sus espacios de trabajo hoy en día. La mayoría de los expertos coincidirá en que el aluminio es siempre preferido sobre otras alternativas porque simplemente funciona mejor en la mayoría de las situaciones. Analizar lo que hace destacar al aluminio nos permite entender por qué sigue siendo tan popular: requiere mantenimiento mínimo, prácticamente dura para siempre y puede soportar cargas considerables sin inconvenientes. Probablemente por eso tantas empresas continúan optando por el aluminio para satisfacer sus necesidades en brazos para monitores, a pesar de los nuevos materiales que van apareciendo.

Validación en toda la industria de las soluciones de aluminio

Las aleaciones de aluminio se han convertido en un material de elección para brazos de monitor, respaldadas por muchas pruebas en condiciones reales y normas industriales establecidas. Grandes nombres en el sector, como Ergotron y Herman Miller, prefieren el aluminio porque ofrece algo especial: propiedades ligeras combinadas con una resistencia sorprendente. Eche un vistazo a cómo trabajan juntas estas dos empresas: no solo están vendiendo productos, sino que realmente colaboran en mejores formas de diseñar espacios de trabajo adaptados a las necesidades digitales actuales. Muchas empresas reportan excelentes resultados después de cambiar al equipo basado en aluminio. Algunas dicen que los trabajadores están más contentos, otras notan una mejora en la eficiencia en los departamentos. La continua soporte de los principales fabricantes muestra que el aluminio no es solo una moda pasajera; encaja perfectamente con lo que las oficinas buscan ahora: configuraciones flexibles que sean fáciles de ajustar y, al mismo tiempo, sean opciones responsables ambientalmente para el largo plazo.

Preguntas frecuentes

¿Por qué es importante la selección de materiales para brazos de monitores industriales?

La selección de materiales es crítica porque influye en la durabilidad, seguridad y cumplimiento con los estándares regulatorios del brazo de monitor. Garantiza la eficiencia operativa y fiabilidad al seleccionar materiales con propiedades adecuadas, como la resistencia a la tracción y la resistencia a la corrosión.

¿Qué propiedades son cruciales para la longevidad de los brazos de monitor industriales?

Propiedades clave incluyen resistencia a la tracción, resistencia a la fatiga y estabilidad química. Estas aseguran que los brazos de monitor puedan manejar movimientos repetitivos, peso y exposición a sustancias reactivas, reduciendo el desgaste y las necesidades de mantenimiento.

¿Cómo afecta la relación entre resistencia y peso al rendimiento en entornos industriales?

La relación entre resistencia y peso determina qué tan bien los brazos de monitor pueden manejar pesos considerables sin ser excesivamente incómodos. Materiales como el aluminio y el fibra de carbono, con altas relaciones entre resistencia y peso, mejoran el rendimiento y la eficiencia, cruciales para entornos exigentes.

¿Qué beneficios ofrecen los aleaciones de aluminio en el diseño de brazos de monitores industriales?

Las aleaciones de aluminio proporcionan durabilidad de grado aeroespacial, resistencia a la oxidación y excelente conductividad térmica. Estos factores los hacen ideales para aplicaciones ergonómicas que requieren un soporte robusto y ligero, y una disipación eficiente del calor.

¿Cómo difieren los requisitos de mantenimiento entre los tipos de materiales?

Las aleaciones de aluminio requieren poco mantenimiento debido a su resistencia natural a la corrosión. El acero exige un mantenimiento regular para prevenir el óxido, mientras que los plásticos de ingeniería resisten la corrosión pero pueden necesitar verificaciones estructurales en escenarios de alta carga.

Tabla de Contenido

- Material Importa: Cómo Brazo de Monitor Industrial Composición Impacta el Rendimiento

- Por qué el Aleación de Aluminio Domina en el Diseño de Brazos de Monitores Industriales

- Confrontación de Materiales: Aleación de Aluminio vs Acero vs Plásticos de Ingeniería

- Conclusión: Aleación de Aluminio como Referencia para Brazos de Monitores Industriales

-

Preguntas frecuentes

- ¿Por qué es importante la selección de materiales para brazos de monitores industriales?

- ¿Qué propiedades son cruciales para la longevidad de los brazos de monitor industriales?

- ¿Cómo afecta la relación entre resistencia y peso al rendimiento en entornos industriales?

- ¿Qué beneficios ofrecen los aleaciones de aluminio en el diseño de brazos de monitores industriales?

- ¿Cómo difieren los requisitos de mantenimiento entre los tipos de materiales?